and Wear Resistant Products

Extremely tough with outstanding wear life properties Vulcanized rubber ceramic liner not only solves ceramic fragile property, but also solve problem of ceramics falling off , so rubber ceramic composite liner steady play its important industrial value. Ceramic wear liners are innovative and high-performance solutions designed to protect industrial equipment and components from the damaging effects of abrasive, erosive, and impact forces. They are a crucial element in industries where materials handling and processing involve the movement of abrasive materials, such as mining, cement, steel, power generation, and chemical processing. Traditional metallic wear-resistant materials have limitations when exposed to severe wear and corrosion conditions. This is where ceramic wear liners prove to be superior alternatives. These liners are made from advanced ceramics, which possess exceptional hardness, toughness, and resistance to wear, making them ideal for demanding applications.Advantages Improved wear lifeCeramic wear plates maximize the lifetime of your equipment, and increase production capacity in both wet and dry applications. Flow improvementImprove poor material flow caused by narrow sectors in the process. Such spots can be real bottlenecks and create a lot of additional work and unplanned downtime. Reduce noise pollutionAll ceramic wear products reduce noise and contribute to a better work environment. Type of Ceramic Material 92% Alumina95% Alumina99% AluminaZTA(Zirconia Toughened Alumina) Zirconium OxideRBSiC Silicon Carbide D3.65D3.72D3.82D4.25D6.10D3.02

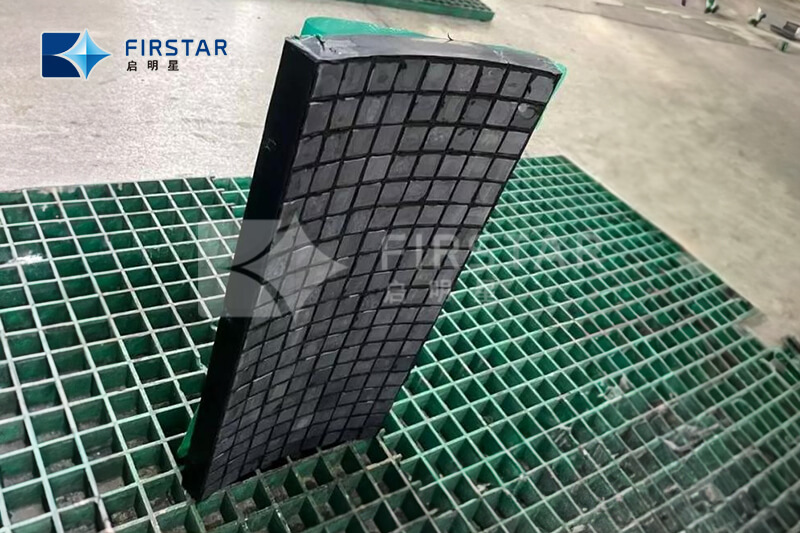

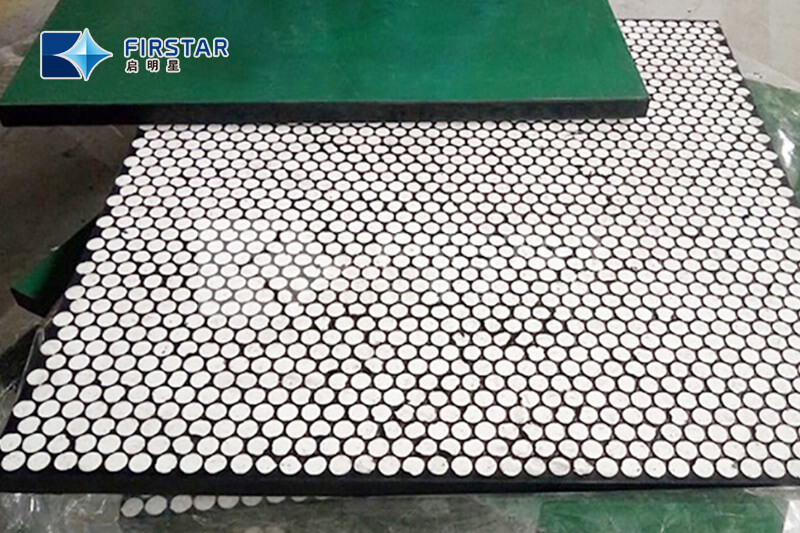

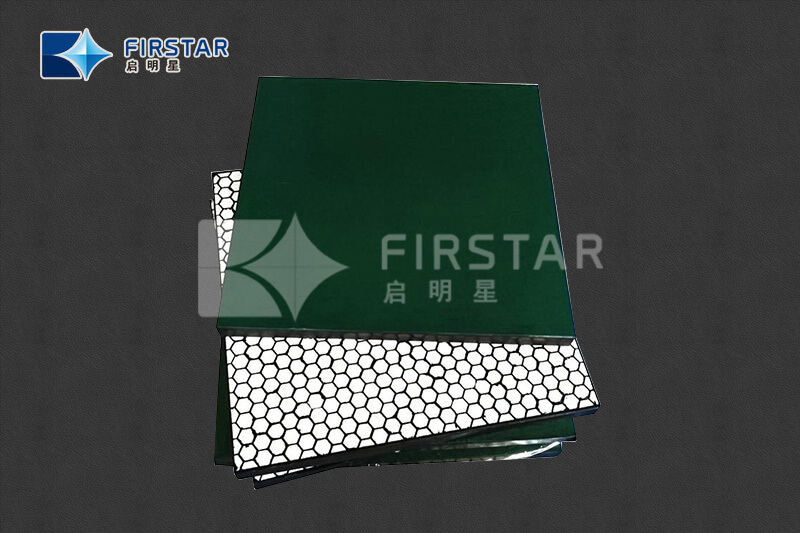

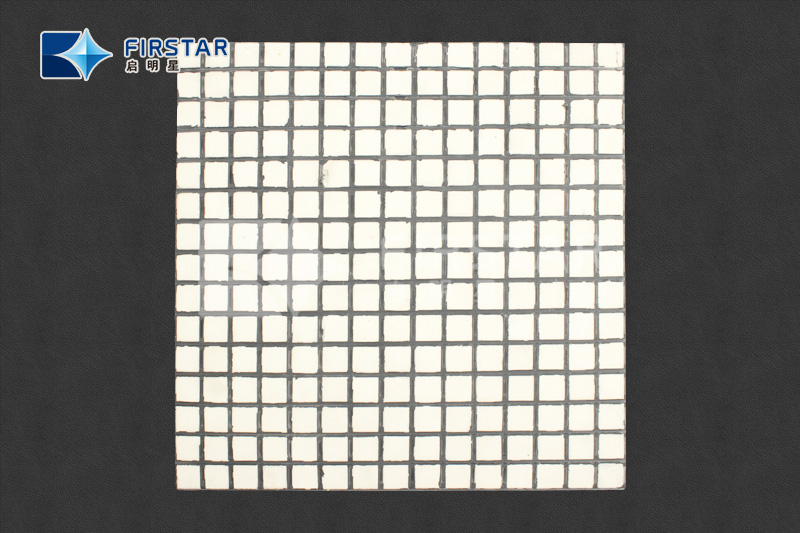

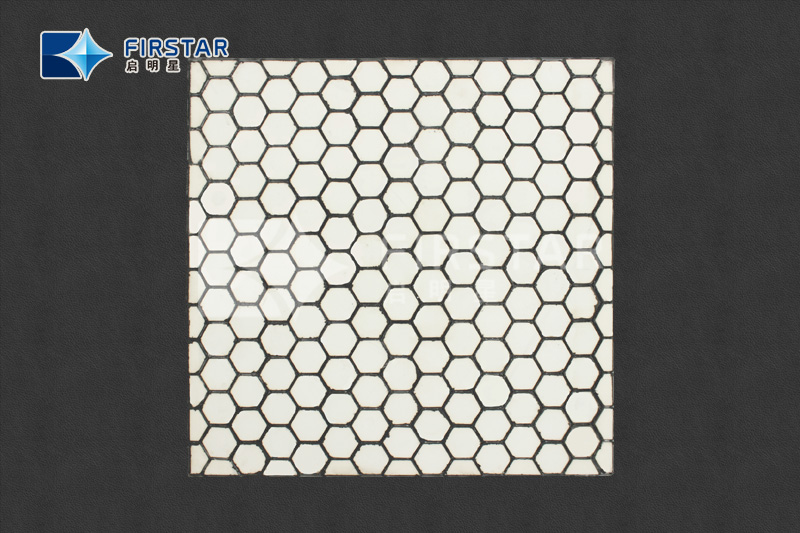

Ceramic/rubber lining material is a composite construction of highly wear-resistant 92 %-Al2O3 ceramic tiles (square, rectangular or hexagonal „SW“) vulcanized in special rubber with CN bonding layer.Properties• CN bonding layer provides fast and longlasting adhesion• Highest abrasion resistance• Reduces operating costs• Long service life increases the efficiency of your equipment• Good resistance against weatherArea of application• Lining against extreme wear through abrasion at high speeds• For simple to medium duty applications in mining, gravel, sand and stone breaking mills and other industrial sectors• In applications like pipelines, vibratory feeders, cyclones, skips, bunkers, chutes, loading points, slides, hoppers, silosSpecificationsPolymer basisNR/BR/SBRDIN ISO 1629Specific weight1.12 g/cm³DIN EN ISO 1183-1Hardness62 Shore ADIN ISO 7619-1ColourBlackRef. No. DesignationDimensionsDimensions of ceramic tilesWeight539 9022 10/4 14 x 500 x 500 mm10 x 20 x 20 mm10 kg539 9039 25/15 40 x 500 x 600 mm25 x 100 x 150 mm32 kg539 9046HEX 6/6 12 x 510 x 525 mmSW 32 x 6 mm

Joined using a special process, the Hybrid Liner combines two liner materials and their favorable properties. The interior is made of polyurethane and protects the residual limb and bony structures thanks to its shock absorbing characteristics. At the same time, it ensures optimum pressure distribution across the entire residual limb, both for passive and active generation of the vacuum. The outside of the liner and the integrated vacuum flap are made of silicone, proven in everyday use thanks to its robustness. This is particularly important when the vacuum flap is folded over the inner socket to create an airtight seal for the system. Application: On the subject of abrasion with respect to rubber linings, the following statements must be considered.1- There are two types of abrasion one may encounter, impingement and sliding.2- Impingement abrasion occurs when particles strike the surface of the rubber (or any other surface).3- Sliding abrasion occurs when another surface slides across the rubber.4- In virtually every case the abrasion can be expected to be a combination of impingement and sliding.5- Predominantly impingement abrasion occurs in chutes, sandblast hose and anywhere rebound is observed.6- In the impingement process, particles hit the surface and any stresses produced are distributed evenly if the rubber yields easily, especially when the particles strike at a 90° angle to the surface.

Canoe Liner Benefits QMX has been manufacturing wear liners of all types for over 25years. From Bolt on to weld in, canoe liners or skirting liners, with steel back or ceramic face we can supply all your requirements. QMX manufacture impact and wear resistant liners in almost any size and shape from the highest quality materials specifically chosen for your environment. We can work with your drawings to assist with liner layout and tag each liner for installation to the layout drawing. We can help you map out your wear lining requirements for any size or configuration.

Chute Linings are designed to be an integral part of a conveyor system. Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build, design, fabricate and install chutes, and also repair and re-align existing chutes.

Keeping product on the line and off of adjacent walkways and equipment is critical to maintaining a safe and productive work environment. Our tough skirting liners are available in solid rubber or a combination rubber/ceramic matrix, our high wearing skirt liners keep ore in line and protect your equipment, saving time and money while increasing production. Handy Tee slot mounting allows for use in skirting or solid wall wear applications and are interchangeable.Solid Rubber or Ceramic / Rubber with steel backing plate and Tee Bolt slots for easy mounting means the entire wear face is solid with no holes to catch material and cause premature wear or bolt deterioration. Liners can be adjusted easily up or down to achieve the best fit.QMX can supply wear and skirting solutions for all types of material conveyance wear and impact areas. Custom liners are available for specialty applications such as wood and food processing and handling.Examples of Use· Conveyor Skirting· Chutes· Hopper wear areas· Impact protection· Material transfer points· Overhead conveyor lines· Primary impact areas· Rail and Port loading terminals· Rock boxes· Screen Deck protection· Screen discharge areas· Screen undersize chutesFeatures: · Highly effective particularly where material is being bulk loaded onto the conveyor to control the material until it becomes stable.· The liners are steel backed and made to fit existing loading stations.· They are manufactured to conform to the belt with the ability to adjust the height to fit the belt and maximize the liner life.· The rubber thickness varies and ceramics can be added to fit the application.· In load-zones with high tonnage rates, Canoe Liners significantly reduce spillage, dust and wear.· Designed specific to your application, then custom manufactured.· Each metal-backed Canoe Liner comes with the ability to adjust the height to fit your conveyor belt.

Ceramics wear resistant· Wear Resistant: Manufactured with fine-grain alumina ceramic which is 12 times more wear resistant than steel· Optimal Arrangement: The exposed ceramic faces are optimally arranged to minimize the base material exposure and extend useful life· Slip Resistant: The embossed ceramic surface greatly improves belt traction· Variety of Options: ceramic tiles are offered in a variety of shapes, sizes, and thicknesses to suit any application Ceramic: 92% & 95% Alumina, RBSiC, ZTAAvailable with square, rectangular, cylindrical or hexagonal,etc.Cushion Rubber/ PU: Superior rubber/PU compound, impact-absorbingConnection: Steel plate and studs / cn bonding layer, both available to suit different types of applicationsThe thickness of complete liner, ceramic and rubber/PU are determined on the basis of application, such as handled material lump size, height of fall, impact angle, etc.

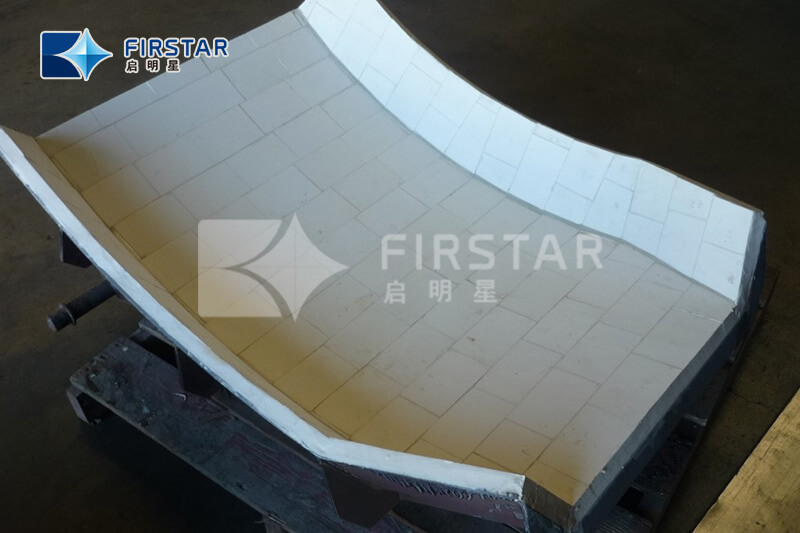

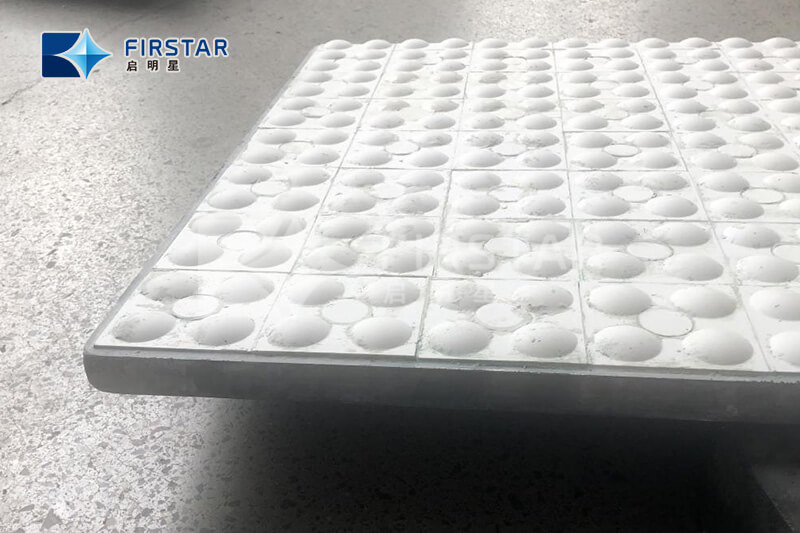

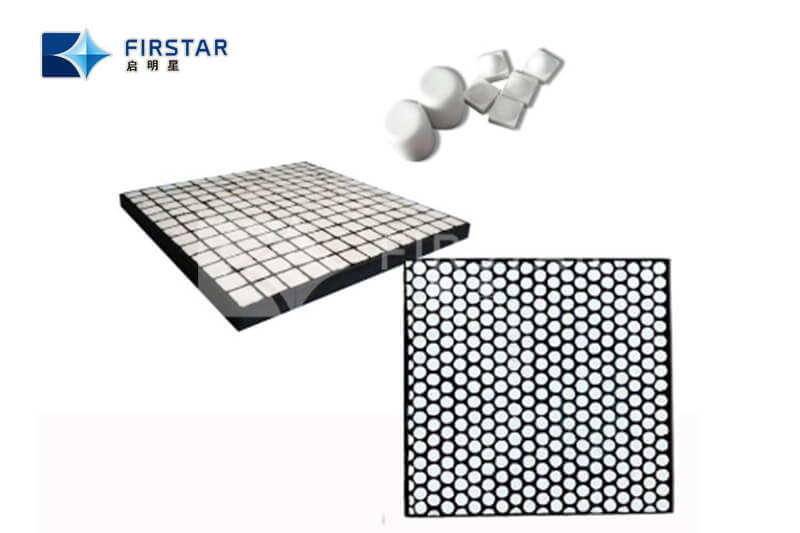

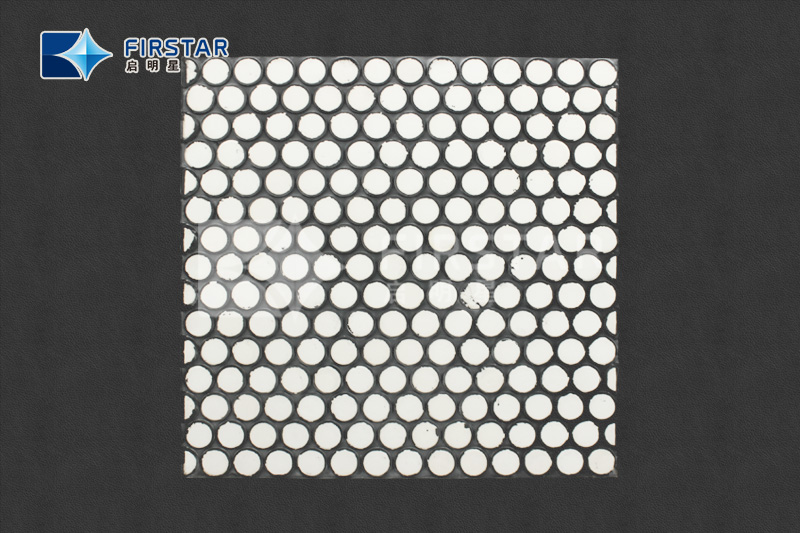

Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Laid out in zigzag and brick pattern, ceramic tiles/cylinders is an excellent feature for handling large material volumes at different angles without developing a wear pattern. As excellent impact and wear resistant material,The panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc. The major applicable industries are Coal fired power plants, cement plants, blast furnace plants and host of other industries which requires high impact abrasion resistant surfaces.Type of CeramicsRubberSteel/Metal 92% AluminaNatural rubberHardness 60 A235A95% Alumina 99% AluminaZTA Zirconia Hex Tile mats Regular sizes:Panel Size300×300,250×250,500×500,600×600mmCeramic size19x19, 21x21, 40x40 Hex tile Alloy Steel Sizealloy steel plate with thickness ranging from 3 mm to 10 mmRubber ThicknessDepends upon the impact stress expected.Remarkmetal+rubber+ceramic / rubber+ceramicplain surface or spherical surface.The steel bolt also available upon requestsPacking:Wooden Crate Ply-Wood Pallet

Rubber Embedded Ceramic Wear Tile Panels alumina ceramics is one of the hardest of all natural substances. Even under extremely abrasive conditions, no material can compete with its extreme hardness and wear resistance. It has exceptional chemical, mechanical, thermal and electrical insulation properties and can be formed into any shape or size with various qualities for specific applications. Ceramic Wear TilesCeramic wear resistant tiles form part of QMX’s range of engineered ceramic solutions. This range of wear solutions provides high-levels equipment protection from material abuses, extending the life of mineral processing equipment in mining, mineral extraction and power generation applications. QMX’s wear-resistant ceramic tiles can be cut into any shape and are easy to install and maintain. They are suitable for both wet and dry processing applications. Advanced ceramics combine high strength and toughness with extreme hardness to deliver exceptional wear resistance.Ceramic wear-resistant tiles are pressed with chamfered sides and cut precisely to the required shape, ensuring that gaps between the ceramic wear-resistant tiles are minimised and tile wear is reduced as chipping is eliminated.Benefits of Ceramic Wear-Resistant Tiles:· Zero friction against minerals· The highest protection against abrasion and corrosion· Wear protection up to 400°C· Longer life than traditional wear protection· Reduce downtime and maximise your plant’s productivityCeramic: 92% & 95% Alumina, RBSiC, ZTAAvailable with square, rectangular, cylindrical or hexagonal,etc.Cushion Rubber/ PU: Superior rubber/PU compound, impact-absorbingConnection: Steel plate and studs / cn bonding layer, both available to suit different types of applicationsThe thickness of complete liner, ceramic and rubber/PU are determined on the basis of application, such as handled material lump size, height of fall, impact angle, etc.

Ceramic/rubber lining material is a composite construction of highly wear-resistant 92 %-Al2O3 ceramic tiles (square, rectangular or hexagonal „SW“) vulcanized in special rubber with CN bonding layer. Properties • CN bonding layer provides fast andlonglasting adhesion• Highest abrasion resistance• Reduces operating costs• Long service life increases the efficiencyof your equipment• Good resistance against weather Area of application • Lining against extreme wear throughabrasion at high speeds• For simple to medium duty applicationsin mining, gravel, sand and stone breakingmills and other industrial sectors• In applications like pipelines, vibratoryfeeders, cyclones, skips, bunkers, chutes,loading points, slides, hoppers, silos

Abrasion is always unavoidable in the processing and transport of bulk materials. The falling material flow causes particularly strong impact. We offer our customers best solutions with the high-quality ceramic wear matrix(with/without steel plate and bolt), in order to achieve an optimal result in increasing the impact resistance and reducing the abrasion and noise. Features:* Extremely high impact resistance* Low friction coefficients*Noise reduction* easy and fast montageApplications:*Lining of funnels and containers*Slides and transfer stations*Pipeline case*Vibration chutes and chute boxes*Application at the transfer pointsType of Ceramics : * Cylinder *Hex Tile* Rectangular* Square*Cube 92%, 95%, 99% Al2O3, ZTA, Zirconium, RBSIC Silicon Carbide Dimension of the Liners: Regular&Customized,Max L800*W800mm

Cold Bonded Wear PanelsQMX Wear Panel solutions are ideal for a wide variety of mining, mineral processing and material handling for protection against extreme wear.ApplicationTypical application examples:· Chutes· Cyclones· Launders· Pipes and tanks· Conveyor transfer points· Screen beams, underpans and components· Vibratory feedersKey features and benefits· 92% Aluminium oxide material.· Rubber compound blended with CN polymers.· Buffed CN bonding layer and buffed edges.· Manageable size and weight. Strip width 250mm makes it easy to install.· Fire resistant and antistatic (FRAS) rubber compound available.· Low sulphur rubber.· Ceramic tiles bonded to rubber on all sides (except top surface).· Supplied in square panels 500mm x 500mm.· Extreme wear resistance.· Outstanding adhesion to ceramic tiles, rubber and metal.· For optimum cold vulcanised adhesion.· Can be used in above and below ground applications.· Stable rubber hardness with age.· Resists tile cracking and pull out.· Easy to install.Rubber,Ceramic&Steel SpecificationS.No.MaterialAttributesProperties1Ceramic TilesMaterial92%, 95%, T95%,99%, ZTA2RubberComponentNatural rubber, nitrile-butadiene rubber ,Flame Retardant ,othersDensity~1.4g/cm3Tensile strength at break≥10.6MpaElongation at break ≥350%Shore Hardness45-65Adhesive between tile and rubber≥3.8 MpaAdhesive between rubber and equipment≥3.58MpaThermal conductivity.(normal temperature)2w/m·kAging period≥15 YearsWorking temperature-50ºC - 200ºC3Steel plateMaterialQ235ADensity7.85g/cm3Thickness3-10mm4AdhesiveAppearanceBrown glutinous liquidSolid content 20±3%Viscosity≥2.5 MpaPeel strength 48h N/2.5cm≥120Compressive strength≥850 MpaWorking temperature-20ºC - 100ºC

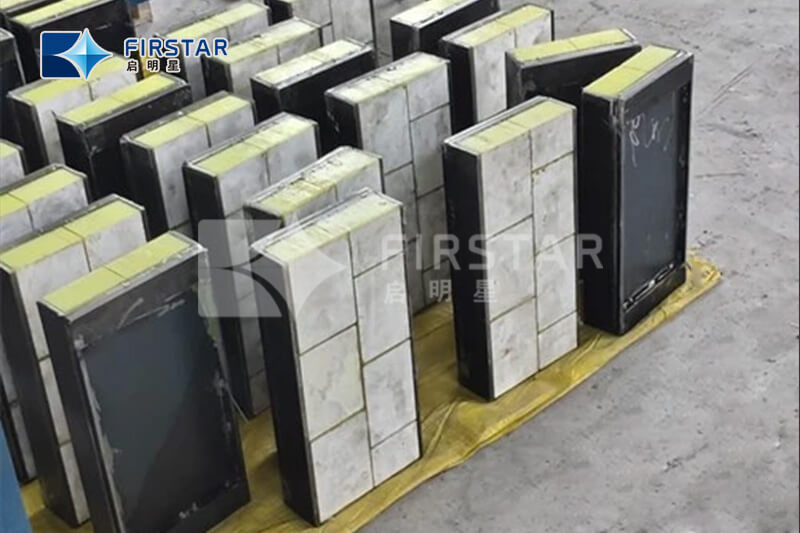

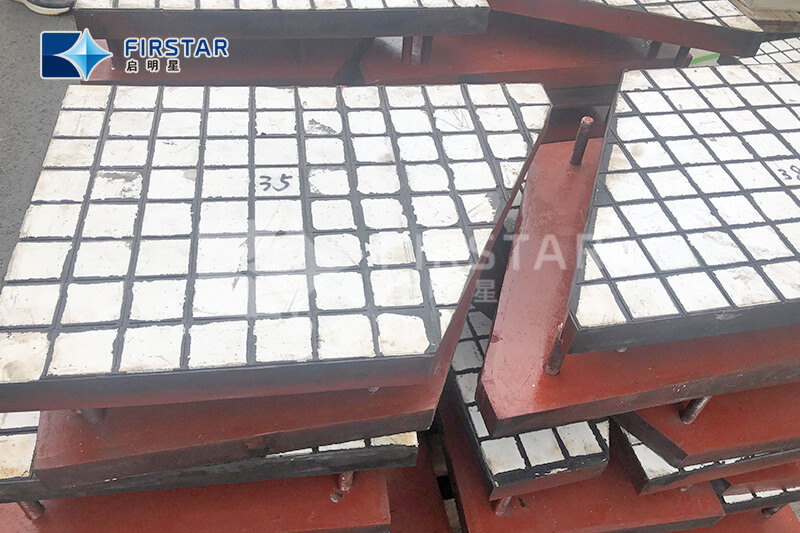

Chute ceramic wear liner tileThe ceramic wear liner backed steel plates are hot vulcanized together with the high tensile strength 7mm nature rubber sheet and 6mm steel backing plate. As a result the ceramics wear liner will have both advantages of the rubber impact resistance and ceramic wear resistance. Size of Rubber backed Alumina wear plates 1NO.sizeceramic+rubber+steelNote1500*500*5028+16+6Hex Tile L23.1xT282300*300*6350+7+6147*97*503300*300*3525+4+6147*97*254298*298*6350+7+6147*97*505190*390*2515+4+6Hex Tile L12.5xT156500*500*2013+1+620*20*137450*400*6350+7+6147*97*508400*300*6350+7+6147*97*509450*300*6350+7+6147*97*5010300*200*3725+6+6147*97*5011300*200*3725+6+6147*97*5012300*150*6350+7+6147*97*5013500*500*5030+14+647.5*47.5*3014500*500*3220+6+647.5*47.5*3015500*250*3220+6+647.5*47.5*3016500*500*2820+2+6φ20*2017500*500*5040+4+6φ40*4018300*300*3320+7+6φ20*2019390*190*6340+17+6φ40*4020302*302*3220+6+6φ20*2021500*500*3220+6+6φ20*20Customized Sizes can be manufactured.FeatureModular Bolt-In SectionsNot Limited to Standard Sizes and ThicknessesHighly CustomizableFast Installation & ReplacementCost EffectiveImpact AbsorbingAbrasion ResistantNoise ReductionLighter Compared to Steel

Superior wear resistance of high alumina ceramics.Energy-absorbing rubber cushions, more impact resistant.Extend wear life of your production line, reduce maintenance and downtime.Alumina ceramic lining is a high abrasion-resistant wear product, it is a combination of high alumina ceramic tiles and natural rubber.High alumina ceramic lining offers wear protection and can extend service life of chute or other equipment significantly, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel. Installation for ceramic lining1. Rubber ceramic lining produced with steel plate and stud-fixed to steel plate by studs, nuts and washers.2. Ceramic lining with cn bonding layer.-be bonded to steel plate by adhesive.3. Alumina ceramic lining can also be produced with steel or aluminum channel-fixed by studs

Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Laid out in zigzag and brick pattern, ceramic tiles/cylinders is an excellent feature for handling large material volumes at different angles without developing a wear pattern. As excellent impact and wear resistant material,The panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc. The major applicable industries are Coal fired power plants, cement plants, blast furnace plants and host of other industries which requires high impact abrasion resistant surfaces.Type of CeramicsRubberSteel/Metal 92% AluminaNatural rubber Hardness 60A235A 95% Alumina 99% Alumina ZTA ZirconiaHex Tile mats Regular sizes:Panel Size300×300,250×250,500×500,600×600mmCeramic size19x19, 21x21, 40x40 Hex tile Alloy Steel Sizealloy steel plate with thickness ranging from 3 mm to 10 mmRubber ThicknessDepends upon the impact stress expected.Remarkmetal+rubber+ceramic / rubber+ceramicplain surface or spherical surface. The steel bolt also available upon requestsPacking:Wooden Crate Ply-Wood Pallet

CERAMIC LINER FOR EXTREME WEAR PROTECTIONMineral Processing equipment operates in some of the harshest and remote locations. It is crucial to the Mineral Processing industries that this equipment continues to operate efficiently and its life cycle is maximized to minimize down time. By appropriately protecting equipment from the extreme wear caused by the high speed and flow rates of ore when processed as a slurry ensures better equipment longevity. Slurry is highly abrasive and can not only cause wear damage to wet processing equipment but also with the inclusion of chemicals and heat, there is constant risk of corrosion and dangerous leakage.Wear Protection Linings are used throughout Mineral Processing to protect the steel surfaces of equipment from wear and corrosion. They are used on a range of equipment including pipes, tanks, chutes, pumps, flotation cells, thickeners, launders and feed spouts or chutes.Composite Ceramic Wear Liners are ideally suited for wear and corrosion protection with the inclusion of extremely high wear resistance ceramic tiles coupled with the impact and energy absorbing resistance of the rubber matrix. This combined effect significantly reduces wear, leakage and the risk of damage to the equipment but also significantly decreases environmental and safety issues for operators.Ultraming supply a range of custom made Composite Ceramic Wear Liners made only from Alumina tiles embedded within a premium grade, wear and impact resistant rubber. These products are designed to be bonded into equipment using the CN bonding layer for ultimate bond strength and can be easily installed in place of existing lining materials such as steel or rubber.Composite Ceramic Wear Liners can be supplied as standard pads, or cut panels to meet customer drawings and specifications, or can be custom engineered to ensure maximum suitability for your specific application.Ceramic Wear Panels can also be supplied with steel backing for mechanical fastening onto equipment for quicker and easier replacement.Ultraming Composite Ceramic Wear Liners last longer, requiring less change-outs, reducing downtime and increasing the productivity of your equipment.

1. Detailed description:In aggressive industrial applications, equipment where high impact , high abrasion inevitably suffer mechanical attack, chemical attack, corrosion, or by a combination of these three modes.QMX’s Ceramics can offer various of ceramic liner plate for customer's abrading environment. Composite ceramic wear liner is intended for the toughest applications with very high materials. when a combination of extreme wear and impact resistance ans long wear life is needed , Ultraming offer composite ceramic wear liner with large and hard ceramic bricks vulcanized into a matrix of wear resistant rubber .due to its elastic properties the rubber acts as a dampener. It makes it possible to use this product in applications with a lot of impact without the risk of crushing the ceramic bricks . 2.Product features:> High hardness > Superior abrasion and impact resistance > Corrosion and chemical resistance > Light weight > Easy installation by epoxy resin or bolt > Improve your working environment-noise, vibration and safety3. The alumina ceramic tiles for vulcanization including:- Square tile: 10x10x2~10mm, 17.5x17.5x2~15mm, 20x20x2~15mm, 33x33x7~25mm, etc.- Ceramic Plate: 100x100x6~50mm, 150x100x6~50mm, etc.- Hexagonal tile: S12xT3~20mm, S19xT6-25mm- Ceramic Block: 40x40x40mm, 32x32x22mm, 38x38x38mm,etc.- Ceramic Cylinder/rod: 6x6mm,15x15mm,20x20mm, 31x31mm , 40x40mm,50x50mm etc.4. The main benefits of the ceramic rubber composites:- Excellent wear resitance- Excellent anti-impact due the elastic property of the rubber- Easy to be installation and then reduce downtime- Reduce the sould pollution.5. Applicatiion of equipments- Bins- Feeders- Chutes- Bunkers- StoragesS.No.MaterialAttributes Properties1Ceramic TilesMaterial92%, 95%, T95%,96%, ZTA2RubberComponentnatural rubber, nitrile-butadiene rubber ,Flame Retardant ,othersDensity~1.4g/cm3Tensile strength at break≥15MpaElongation at break≥250%Shore Hardness45-65Adhesive between tile and rubber1.2-3.0 MpaAdhesive between rubber and equipment≥3.5 MpaThermal conductivity.(normal temperature)2w/m·kAging period≥15 YearsWorking temperature-50ºC - 200ºC3Steel plateMaterialQ235ADensity7.85g/cm3Thickness5-6mm4AdhesiveAppearance Brown glutinous liquidSolid content20±3%Viscosity≥2.5 MpaPeel strength48h N/2.5cm≥120Compressive strength≥850 MpaWorking temperature-20ºC - 100ºCWhole Plate (mm)150x300, 300x300, 450x000, 500x500, 600x450 etc.Ceramic Size (mm)Square Tile: 10x10, 20x20, 33x33, 50x50, 100x100, 150x100,etc.Hexagonal Tile: 12x3, 12x6, 19x7, 19x12.5, 19x25,etc.Locking block with lock and groove: 38x38, 40x40, 30x30,etc.Dimple Tile: 20x20 with 5 dimples, 20x30 with 18 dimples, 20x30 with 13 dimples, 20x20 with 1 semi-spherical surfaceCeramic Thickness (mm)3-75mmAlloy Steel Size (mm)Thickness: 3-10mmRubber Thickness (mm)Depends on the impact stress expected.

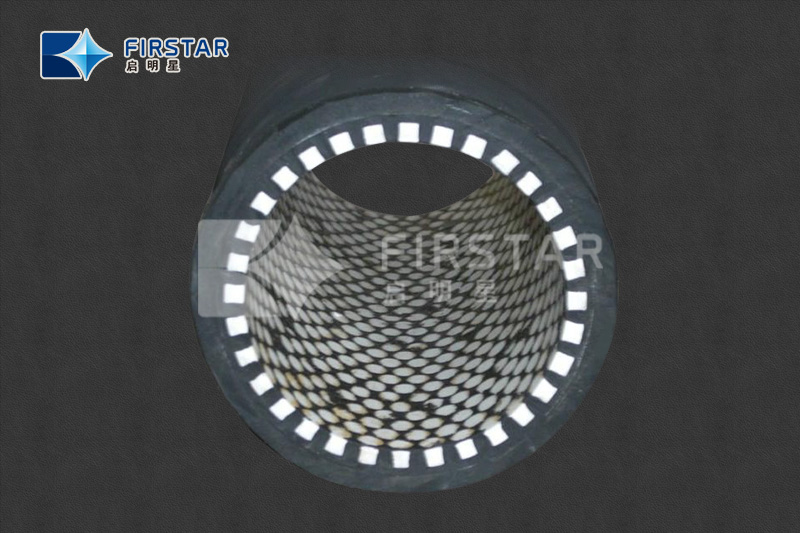

Ceramic lined flexible rubber hoses ceramic-lined flexible hoses are ideal for use in highly aggressive services where conventional rubber hose, expansion joints, or bellows connections require frequent replacement. QMX hoses may also be used to isolate mechanical vibration or to connect non-stationary equipment.Dry abrasion line of powder delivery(Sand, grid, powdered coal, grain, cement and other fine powder)For both delivery and suctionFeaturesAbrasion ResistanceComposite of aluminum ceramics and rubber with high elasticity and strength for inner material.Excellent abrasion resistance against dry abrasion.Inner Rubber LayerInner rubber is complied by composite of ceramic balls (diameter ø3 to ø10) or Hex ceramic tiles and binder rubber with strong adhesion.Ceramic lining is 12 times more wear-resistant than stainless steelImpact resistant - virtually impossible to destroy the ceramic segmentsFlexible - minimum bend radius is roughly 12 times the hose I.D.Corrosion-resistant - compatible with most chemicals found in slurriesWide variety of end-connectionsPurchase any continuous length up to 65 feetTechnical SpecificationsSize Range: 1" to 12" I.D.Pressure Rating: 150 psig.Temperature Range: -100° F to 250° FEnd-Connections: Flanged, plain, etc.Standard SpecificationWorking Pressure: 0.98MPa, Max. Length: 10mN.D.in.I.D.mmO.D.mmWeight kg/m25125.4523.7322001/1/431.8584.2402001/1/238.1665.150250.8796.1622002/1/263.5937.475376.21058.51004101.613811.9125512716619.71506152.419224.4OD and weight data is not garanteed, and may be changed due to working pressure and service condition.