and Wear Resistant Products

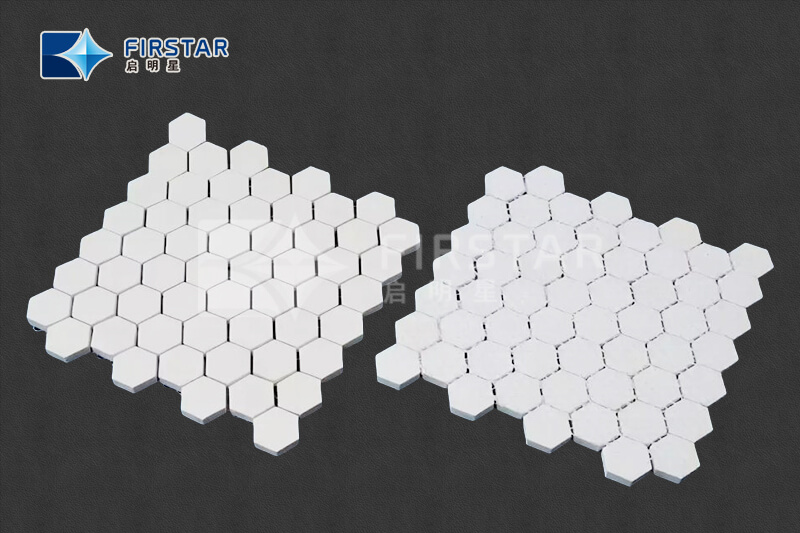

Hex Ceramic Tile Lining KitCeramic liners provide long lasting solutions to the problems caused by abrasive wear and corrosion in a variety of hostile environments.Our Alumina ceramic linings will outlast lower grade materials commonly used to line or protect processing and material handling equipment by factors of 3 to 15 times. Tile linings are often used in grain transitions, grain spouts, grain elbows, grain chutes, grain conveyors, hopper bins, grain valves and grain gates.For use on Curved Surfaces where flat tiles will not work.Dimensions: 6" x 6" Mats,12"x12"mats ; 1/8", 1/4" , 1/2" ,1" ThickPrices are Per MatTechnical SpecificationsCeramic Material: 90% fine-grain aluminaSurface Finish: As-FiredDimensional Tolerance: ±1.5%Maximum Temperature Limit: 1,500° CAlumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel.Advantages:1. High hardness, its Rockwell hardness is HRA80-90, the hardness is second only to diamond2. Long service life, under the same working conditions, the service life of the equipment can be extended by more than 10 times.3 Light weight, its density is 3.6g/cm3, which can greatly reduce equipment load.4. The bonding is firm and the heat resistance is good. The hexagonal ceramic tile mat is pasted on the inner wall of the equipment with heat-resistant super glue.Application:Widely used in anti-wear material conveying systems in coal, thermal power, steel, cement, mining, port, chemical and other industries, such as coal washing plants, thermal power plants, coal pipes, coal hoppers; coke hoppers in steel plants; mining transfer hoppers; cement plant clinker, cement chute, hopper.

Abrasion resistant liningOur Alumina abrasion resistant ceramic linings are highly durable and have a significantly longer lifespan compared to lower grade materials typically used for lining or protecting processing and material handling equipment. These linings can outlast these lower grade materials by factors ranging from 3 to 15 times.One common application for our Alumina ceramic linings is in grain transitions. These transitions are areas where grains are moved from one section to another, and they are prone to wear and tear due to the abrasive nature of the grains. By using our ceramic linings, these transitions can be protected and their lifespan can be extended.Similarly, grain spouts, grain elbows, and grain chutes are also susceptible to abrasion and deterioration. Our Alumina ceramic linings provide excellent resistance against wear, allowing these components to withstand the constant flow of grains without experiencing significant damage. This greatly reduces the need for frequent replacements and maintenance.Grain conveyors, hopper bins, and grain valves are other critical equipment in the grain handling industry that can benefit from our ceramic linings. These components are exposed to high levels of abrasion and impact as grains are transported and processed. By installing our Alumina ceramic linings, these equipment can be protected from wear and damage, resulting in improved reliability and reduced downtime.Overall, our Alumina abrasion resistant ceramic linings offer superior longevity compared to lower grade materials commonly used in the industry. By choosing our ceramic linings, businesses can significantly reduce maintenance costs, minimize equipment downtime, and extend the operational lifespan of their processing and material handling equipment.

ceramic wear resistant linings· Flat ceramic tiles of various dimensions and thickness.· Pre-engineered pipe ceramic tiles.· Interlocking tilesother specialized ceramic products· Monolithic and sets· Pre-engineered inserts and sets· Ceramic tiles and related products used by AVIOCEAN GLOBAL are made to very specific specifications and maintain a high grade of no less than 92% alumina content which is wear resistant ceramic tiles. It counters moisture and creep sulphide attack. Tiles are embedded into an epoxy adhesive applicable to the application.· This lining increases the life span of steel and related products which are subject to severe erosion. Tiles are available in various dimensions and thickness, as required by each application. Pre-engineered ceramic tiles are also available for piping of various diameters and specialized pre-engineered sets for cyclones and similar applications.

Conveyor Chute Wear Resistant Ceramic Rubber Liner is made of high alumina ceramics and high-quality natural rubber compounded by a special process. DescriptionThe Conveyor Chute Wear Resistant Ceramic Rubber Liner is made of high alumina ceramics and high-quality natural rubber compounded by a special process. The excellent shock absorption properties of natural rubber help to achieve a certain impact resistance, thereby preventing the tiles from cracking in the high impact area, which has a very superior effect compared with the ceramic lining tiles directly bonded to the steel plant. Compared with wear-resistant steel, the characteristics of high-quality Conveyor Chute Wear Resistant Ceramic Rubber Liner make it more resistant to wear and impact. Their service life is much longer than previous wear-resistant lining products, and can last for multiple shutdown cycles without causing serious wear or failure.S.No.MaterialAttributesProperties1Ceramic TilesMaterial92%, 95%, T95%,99%, ZTA,RBSIC2RubberComponentnatural rubber, nitrile-butadiene rubber ,Flame Retardant ,othersDensity~1.4g/cm3Tensile strength at break≥15MpaElongation at break ≥250%Shore Hardness45-65Adhesive between tile and rubber1.2-3.0 MpaAdhesive between rubber and equipment≥3.8 MpaThermal conductivity.(normal temperature)2w/m·kAging period≥15 YearsWorking temperature-50ºC - 200ºC3Steel plateMaterialQ235ADensity7.85g/cm3Thickness5-6mm4AdhesiveAppearanceBrown glutinous liquid Solid content20±3%Viscosity≥2.5 MpaPeel strength48h N/2.5cm≥120Compressive strength≥850 MpaWorking temperature-20ºC - 100ºCApplication of Conveyor Chute Wear Resistant Ceramic Rubber Liner Conveyor Chute Wear Resistant Ceramic Rubber Liner provide wear-resistant linings for various equipment, chutes, pipes, hoppers, dustbins, cyclones, screening equipment linings and other industries.

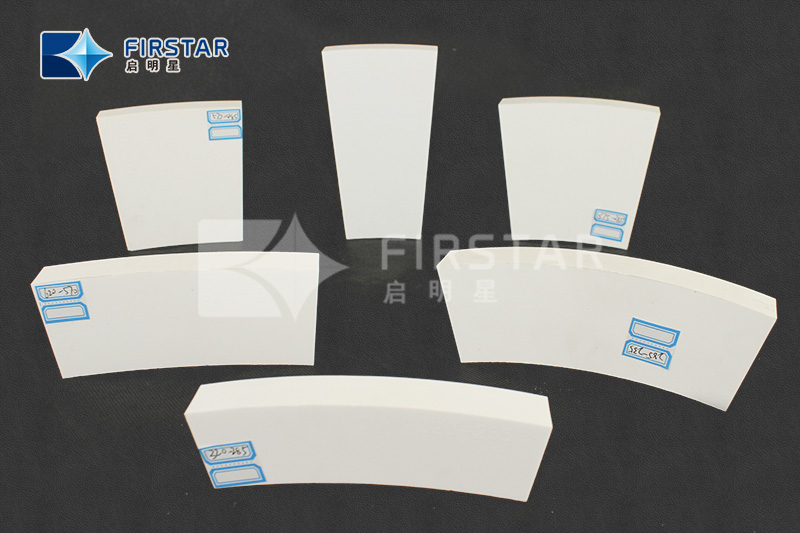

Trapezoidal Pipe Ceramic Lining PlateProduct Introduction:Trapezoidal pipe ceramic lining plate is suitable for wear-resistant lining of pipes and elbows with a diameter of less than 900mm. Trapezoidal lining plates of various specifications can be customized according to the diameter of pipes and elbows, so that they become a complete circular surface during final construction. The board is tightly combined with the board. The wear-resistant ceramic lining plate of the trapezoidal pipe is fired in a tunnel kiln, and the kiln temperature is stable. The fired ceramic lining plate is uniform in color, which has the texture of jade, and the surface is neat and free of black spots.Advantages:Trapezoidal pipe ceramic lining plate has the characteristics of wear resistance, corrosion resistance, high temperature resistance, high impact resistance and convenient construction. It’s the ideal material for surface wear of conveying equipment. It is very safe and reliable to use the trapezoidal pipeline wear-resistant ceramic lining in the occasion of high temperature corrosion, high temperature wear or high temperature erosion.Under the same industrial and mining conditions, its service life is 10 to 20 times of the life of cast stone, wear resistant alloy cast steel, steel plastic, steel rubber and other materials.ItemLengthWidthThicknessAlumina palin Tile50-150mm25-100mm6-50mmAlumina Weld-on tile ( Weldable tiles)50-150mm30-100mm10-50mmAlumina Pipe tile(Trapezoidal)50-150mm20-100mm8-50mm

92% Alumina Wear LiningsAlumina Wear linings are protective covers installed in areas subjected to wear. They are widely utilized in mining, aggregates and cement industries processing hard materials that are tough on equipment. The right wear lining prolong the lifetime of equipment, improve material flow, reduce noise, and thus increase the production capacity. ★Applications Be used in Coal, petroleum, steel, coal fired power generation industries, etc. As the wear-resistant liner to protect the surface of the transport equipment being worn.★FeaturesBeing fired under high temperature, wear-resistance, shock resistance, acid and alkali resistance, its theory wear-resistance is equivalent to 260 times of manganese steel, 170 times of chromium steel, can enhance the life time of equipment.★Size(We could produce as your required)Item(Length)mm(Width)mm(Thickness)mmNote150×1001501006-50Flat tile150×10015010012-20Welding tile with hole100×1001001006.5-15Flat tile10×10 mat10103-10Square17.5×17.5 mat17.517.54-10Square20×20 mat20203-20Square11.55×11.55 mat11.5511.553-10Square12.5×12.5 mat12.512.53-10Square50×5050505-15Flat tile120×80120806-20Welding tile with hole150×601506010-25Flat tile100×81.6/78.510081.6/78.520Curved tile

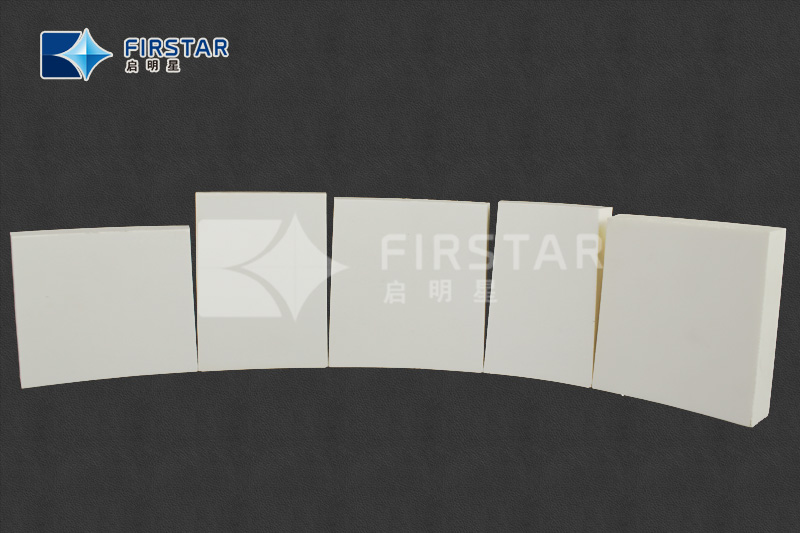

QMX Ceramic Tile is a preferred liner option in areas of extreme small particulate abrasion with minimal impact. The 90% fine grain, high grade alumina is manufactured to the highest standards, producing a premium product that can hold up to your most abrasive materials. Ceramic tiles offer great mechanical properties with superior sliding abrasion resistance.QMX Ceramic Tiles are offered in several thicknesses to address the requirements of your specific application. QMX Tiles are offered with a choice of attachment methods for optimal performance.ADVANTAGES· Greatest Level of Sliding Abrasion Resistance· Cost Effective· Multiple Thickness Options· Chemical Resistance Attachment Options: Epoxy or Weld-in STANDARD THICKNESSESThickness1/4″=6mm1/2″=12mm3/4″=20mm1″ =25mm2″ = 50mm

Ceramic tiles have excellent abrasion and wear resistant qualities and are ideal for use in transfer chutes, piping systems, hoppers, etc. Typical markets include grain, coal-fired power generation, mining, cement, and more.QMX Manufactures a full range of high-density, fine-grain, wear-resistant alumina ceramic wear tiles to prevent erosion and abrasion in conveying and bulk material handling systems. Our alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Weldable tiles are provided with a hole though the tile, a carbon steel weld cup, and a ceramic plug for welding in pace onto a steel substrate.LengthWidtThickness50501550501750502060203560401070701070701575752075752575753075753510050810050121005012.510050151005020100502510075121007520100752510075301001001010010012100100151001002010010025100100301001003510010040100100451208081208010120801212080141208015120802012080251208030150501015050121505012.71505015150502015050251505030150503515050401505050150100101501001215010014150100151501002015010023.5150100241501002515010030150100401501005015010070

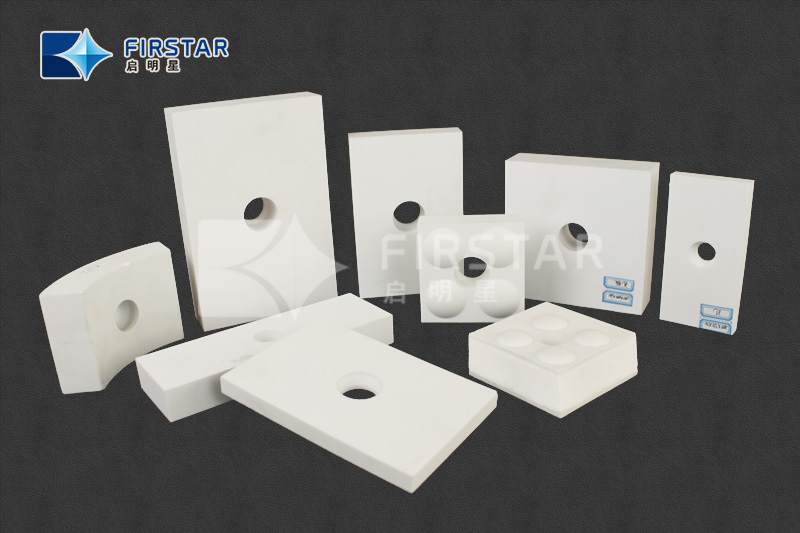

Wear-resistant elements prevent destruction in the transportation, processing, mining and other technological equipment. The elements are made of high-purity, finely dispersed, alpha-alumina. Wear-resistant plates can be made from a variety pre-designed element of different dimensions and forms. 1. Standard tiles(alumina plain tiles)Standard ceramic tiles are used for protection against wear, especially on the flat and straight-line surfaces. Special sizes are on the Customer's request. 2. Weld-on Tile Welding tiles have a hole, and complete with carbon steel riveting and a ceramic plug for welding 3. Ceramic Mosaic Ceramic mosaic is widely used as a lining (facing) tile in the conveyor equipment to protect the drive pulleys of belt conveyors from wear, increases the tape engagement ratio, excluding its slippage. 4. Mosaic matsThe mosaic mats consist of small mosaic tiles glued to acetate silk or PVC mounting film. Standard mats are 250x250 and 500x500 mm. Standard thickness is 3-12 mm. The mats consist of a square tile of 10x10 or 20x20 mm, or a hexagonal tile of SW20/40 mm. Special sizes are on the Customer's request. 5. Ceramic tubesCylinders and spherical segments provide solid protection for steel pipes from abrasive and corrosion wear, even with a small wall thickness. Standard dimensions of inner diameter are 40-500 mm. Special sizes are on the Customer's request. 6. ZTA ceramics The combination of aluminum oxide and zirconium dioxide (ZTA) increases strength, toughness, hardness and wear resistance in 20-30% in comparison with pure alumina ceramics. The maximum temperature for application of products from ZTA ceramics is 1450 ° C. 7. Customized elementsIt is possible to design and manufacture a comprehensive wear-resistant protection and to adapt protective schemes for the Customer's tasks. Special processing of products prior to sintering allows to manufacture products of complex three-dimensional shape.

QMX supply and install a wide range of Alumina Wear Resistant Tiles for wear protection of all areas such as Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans etc.Described as the material of the future, alumina ceramics is one of the hardest of all natural substances known to man. Under extremely abrasive conditions, no material can compete on a cost to life basis with it's extreme hardness and wear resistance. In addition, alumina ceramics has exceptional chemical, mechanical, thermal and electrical insulation properties and can be formed into any shape or size with various qualities for specific applications. Weld-On alumina ceramic tiles are typically used in high temperature applications and are available in most sizes to suit your application on an ex-stock basis.CategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3

Curved pipe tile liner is a excellent wear-resistant material mainly pasted on the inner wall of pipeline or cyclone.It can reduce the wear and tear of the equipment and prolong its service life. According to different pipe curvature and length, we can customize different products for customers.Application:Curved pipe tile liner is mainly pasted on the inner wall of pipes, elbows and hydrocyclones in chemical, cement, mining industry etc.Properties:high hardnessimpact resistancecorrosion resistance

QMX’s engineered ceramic solutions provide a complete range of ceramic wear resistant tiles (9.0 on the Mohs scale) that extend the wear life of your mineral processing equipment in the mining, mineral extraction and power generation industries.These ceramic tiles provide a hard wearing solution in the mining industry, with vibrating feeders, transfer chutes, cyclones, pipes and other traditional "high-wear areas". Engineered tiles are pressed with chamfered sides and then cut precisely while still in their green state, to the required shape. This ensures that gaps between the tiles are minimised and wear of the tiles is reduced as chipping is eliminated.Our Features & Benefits l Polishes to a smooth glassy surface – zero friction against minerals.l Provide the highest protection against abrasion and corrosion.l Easily installed, maintained and replaced. l Suitable for wet and dry processing applications.l Wear protection up to 400°C.Technical Data:CategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3

Alumina ceramic tiles for coal and other material handling and processing industries. Ceramic linings provide long-lasting solutions to the problems caused by abrasive wear and corrosion in a variety of hostile environments. Alumina ceramic linings will outlast lower grade materials commonly used to line or protect processing and material handling equipment, including Basalt, stainless steel, carbon steel and wear resistant plates, by factors of 3 to 15 times.QMX’s wear resistant ceramic tiles can be cut into any shape and are easy to install and maintain. They are suitable for both wet and dry processing applications. Advanced ceramics combine high strength and toughness with extreme hardness to deliver exceptional wear resistance.The ceramic pipe tiles,also cale taper tile or Trapezoidal tile, are used on a range of equipment including pipes, tanks, chutes, pumps, flotation cells, thickeners, launders and feed spouts or chutes.CategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3

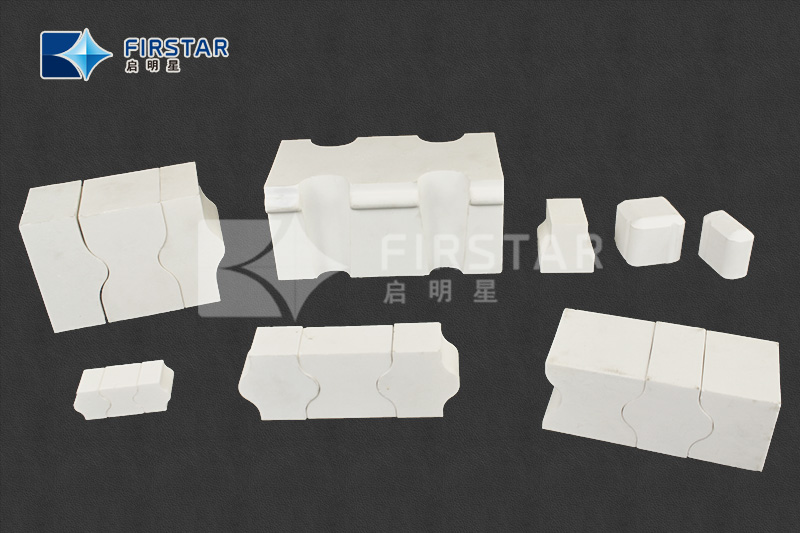

1. Detailed description:alumina cubesThe Ceramic Cube is a high-performance abrasion and impact resisting linings for high-impact, high-pressure applications in which ceramic tile may not have sufficient structural resistance, and high-performance rubber may not offer the required wear life. In extreme applications, the Cube liners can be installed in a matrix or abrasion resistant steel plate to provide structural support for the ceramic/rubber matrix and provide exceptional wear life where competing products cannot.Used in heavy industry for years as a cost-effective, wear-resistant solution, these lightweight materials offer high durability, strength, and excellent abrasion and corrosion resistance. Alumina wear resistant compositions include:l Alumina 92: most common wear product with great wear resistancel Alumina 95: increased wear performancel Alumina 96: premium alumina for best wear resistancel Zirconium toughened alumina(ZTA): increased strength and impact resistance2.Product features:> High hardness > Superior abrasion and impact resistance > Corrosion and chemical resistance > Light weight > Easy installation by epoxy resin or bolt > Improve your working environment-noise, vibration and safety3. Product Specification:- Square tile: 10x10x3~10mm, 17.5x17.5x3~15mm, 20x20x3~15mm, etc.- Ceramic Plate: 100x100x6~50mm, 150x100x6~50mm, etc.- Hexagonal tile: S12.5xT3~20mm, S23.5xT6-25mm- Dimple tiles: 20x20x4-10+1(with 5 dimples), 20x30x5~15+1(with 18 dimples), 20x20x5-10mm( with 13 dimples)- Ceramic Block: 40x40x40mm, 45x45x50mm,32x32x22mm, 38x38x38mm,etc.- Ceramic Cylinder/rod: 6x6mm,15x15mm,20x20mm, 31x31mm,40x40mm, 45x50mm, 50x50mm etc.4. Ceramic wear lining tiles for a variety of applications:Processing equipment:l Pharmaceutical clean roomsl Food processing plantsl Grain handlingl Mineral processingl Cement manufacturingl Chemical processingl Large Cyclones:l Coal-fired power plantsl Steel Millsl Asphalt Plantsl Petrochemical plantsl Pulp and paper millsCategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3