and Wear Resistant Products

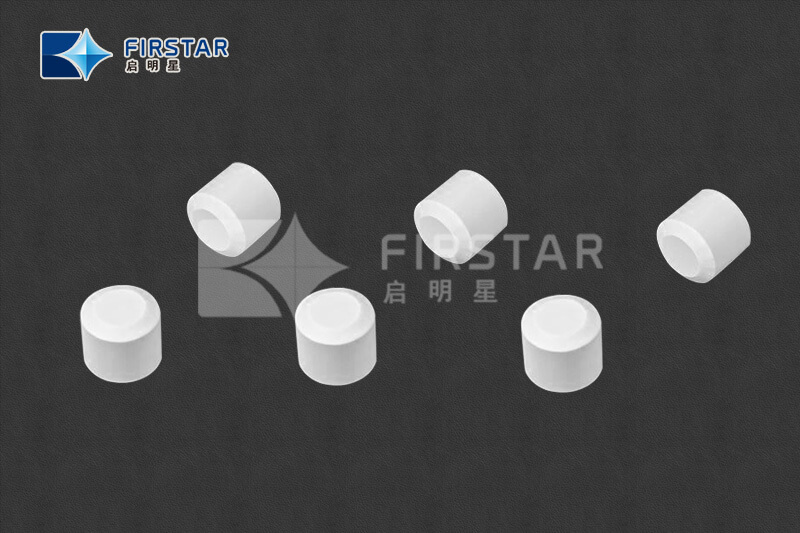

A White, Solid, Powerful Ball Milling SolutionWhen you can’t use steel in your ball mills because of contamination, what do you do? QMX Alumina Balls are the answer. The unique microstructures of QMX Alumina Balls result in hard, chemically inert grinding Media, that are corrosion resistant, non toxic, non magnetic, and non porous.This alumina grinding media possesses excellent thermal properties. So you can grind down to the particle size you need to achieve.Better for some applications than porcelain, flint pebbles, or natural stones, QMX Alumina grinding balls are precisely engineered, down to the nanometer.Because when it comes to your ball milling process, every nanometer counts. DESCRIPTIONPROPERTIESShapeSpherical, CylindericalCompositionAlumina Oxide 92%/95%ColorWhiteSize0.5-60 for Spherical 5x5, 7x7, 10x10,15x15 for CylindericalDESCRIPTIONPHYSICAL PROPERTITIES OF 92% ALUMINADensity3.65g/Cm3Hardness9 Mohs DESCRIPTIONPHYSICAL PROPERTITIES OF 92% ALUMINADensity3.70g/Cm3Hardness9 Mohs ALUMINA CERAMIC GRINDING COLUMN/Cylinder BENEFITSAlumina Ceramic Grinding Cylinder has high strength, high hardness, high wear resistance, large specific gravity, small size, high-temperature resistance, corrosion resistance, pollution-free, and other excellent properties. Alumina Grinding column are also used for grinding bodies of fine grinding equipment such as ball mills, pot mills, and vibration mills. Alumina Cylinder Grinding Media ApplicationQMX suggest Al2O3 alumina grinding cylinders for stirred mills and ball mills preferably. Alumina grinding columns are widely used in different types of ceramics, enamels, glass, chemicals, etc. due to their excellent characteristics such as high strength, high hardness, high wear resistance, large specific volume, small volume, high-temperature resistance, and corrosion resistance.· Fine grinding of industrial mineral like alumina, zirconia silicate, feldspar, quartz, kaolin clay, glaze, inks and ceramics.· Suitable for wet grinding.· Recommended in Stirred and Ball Mill. Not recommended for high speed stirred mills and sand mills.

CERAMIC PIPE LINING Y-Type TeeMonolithic & Mosaic Advanced CeramicsQMX Ceramic Solutions offers a range of ceramic materials for your pipe lining applications. QMXcan offer advanced ceramic materials in both monolithic and mosaic forms for your pipe and equipment lining applications.QMX Ceramic Solutions offers a complete material portfolio of ceramic materials including; Aluminum Oxide, Zirconium Oxide, Zirconia Toughened Alumina and a variety of sintered and reaction bonded Silicon Carbide compositions for your extreme corrosion, abrasive and wear environments. Carbon-Graphite bearing and seal face materials are also available upon request. Application range· coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a wind pipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;· iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;· cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high temperature air blower, lower material pipe, etc.;· petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery and other processing and conveying material pipe.

Alubit High Alumina ceramic Grinding Cylinder is used as grinding media for ceramic body and glaze preparation. It’s high purity and low abrasion loss make it to be suitable for both wet and dry superfine grinding of alumina, zirconium silicate, glaze, kaolin clay, quartz, feldspar, inks and ceramics in ball mill.Product Features:(1)Excellent wear and corrosion resistance; Chip-proof, acid-resisting, alkali-resisting, anti-abrasion, high thermal shock resistance;(2)High density and small thickness can increase the effective ground space and increase the yield;(3)Low wear loss and long service life (it is 3-5 times compared with nature stone liner and 23 times compared with rubber liner),which can reduce the installation times;(4)Main material is alumina which has no pollution to the grinding object,Easy to clean;(5)Shorten milling time and increase efficiency. Application:QMX High Alumina Grinding Cylinder is used as grinding media for ceramic body and glaze preparation. It’s high purity and low abrasion loss make it to be suitable for both wet and dry superfine grinding of alumina, zirconium silicate, glaze, kaolin clay, quartz, feldspar, inks and ceramics in ball mill.Technical Data: Specification (Size):Product Diameter (mm)Height(mm)CylinderD30/40 /50/ 60D30/ 40/ 50 /60(with chamfer ) R0.5R0.5Remark: Any other sizes are available upon customer’s requests.CategoryHC92HC95HCT95Al2O3≥92%≥95% ≥ 95%ZrO2///Density≥3.60g/cm3≥3.65g/cm3≥3.70g/cm3Water Absorption ≤0.1%≤0.1%≤0.1%HV 20≥950≥1000≥1100Rock Hardness HRA≥82≥85≥88Bending Strength MPa≥220≥250≥300Compression strength MPa≥1050≥1300≥1600Fracture Toughness KIc MPam 1/2≥3.7≥3.8≥4.0Wear Volume≤0.25cm3≤0.20cm3≤0.15cm3Benefits> Suitable for wet grinding and dry grinding> Forming by HIP isostatic pressing makes the cylinder’s hardness is better than the rolled grinding ball.and the chamfer edges makes the cylinder smoother to grind.> The high purity raw material of Australia alumina powder and technology keep the media in the best to wear the abrasion and also could keep the grinding time longer than other grinding media. Product Packaging: PE Bag (25kg/bag)+Pallet

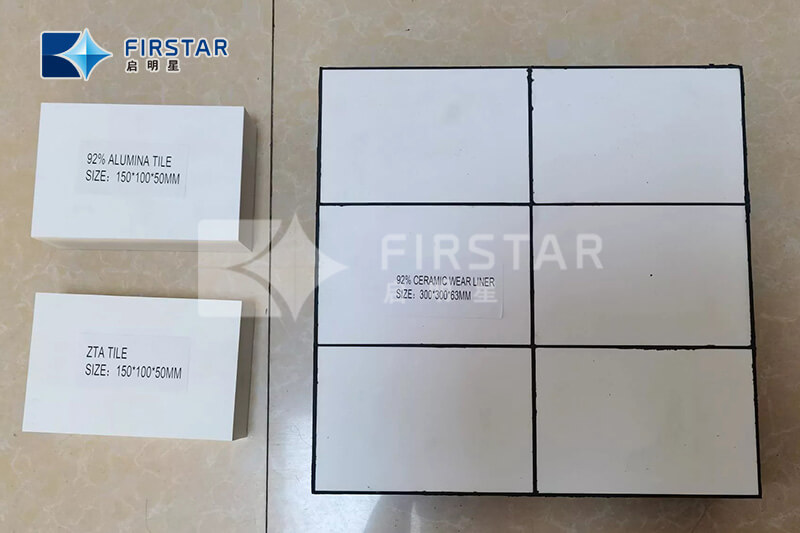

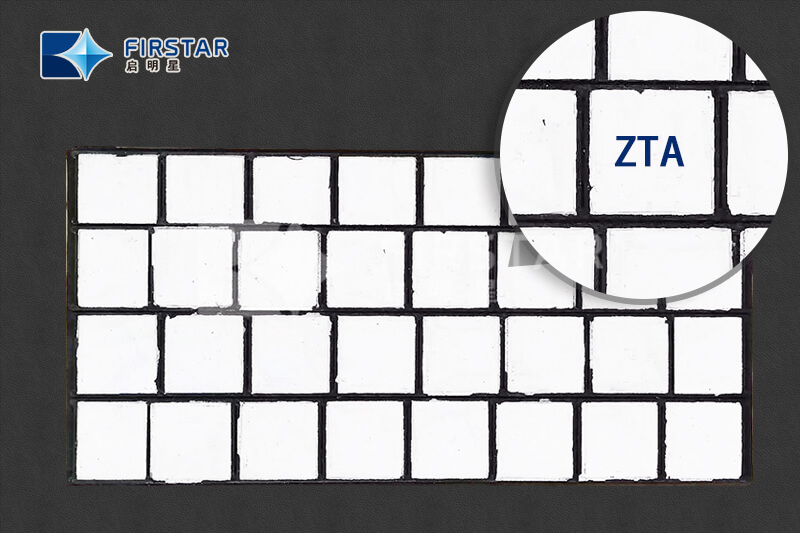

ZIRCONIUM TOUGHENED ALUMINAZTA - Aluminum ZirconiumZTA(Zirconia Toughened Alumina)Liners Zirconia Toughened Alumina Ceramics also named ZTA ceramics, zirconium oxideceramics, which is white, corrosion resistance, chemical stability,a special combination ofaluminum oxide and zirconium oxide. QMX Ceramics technicians mix high purity aluminawith zirconia by the process of transformation toughening,making composite ceramic linermore tougher,harder,wear resistance over alumina alone,and lower cost than zirconia. Zirconia toughened alumina is a composite of alumina and zirconia which leads to an increase in strength and fracture toughness as compared to other aluminas.INCREASED FRACTURE TOUGHNESSThe high fracture toughness gives it very good edge strength and makes the material ideal for components subjected to impact loading.EXCELLENT WEAR RESISTANCEDuring the sintering process, an extremely smooth microstructure is achieved which leads to superior wear performance.GOOD THERMAL CONDUCTIVITYZTA materials provide for good dissipation of heat generated by friction. Chemical composition:% ZrO2: 20.8%Al2O3: 76.8%Physical properties: Density: 4.216g/cm3Compressive strength: 1150MpaVikers Hardness HV10: 1481MpaTotal Porosity: 1.6%Fracture toughness(KIC (MPam-1/2): 3.5Wear volume: 0.15cm3

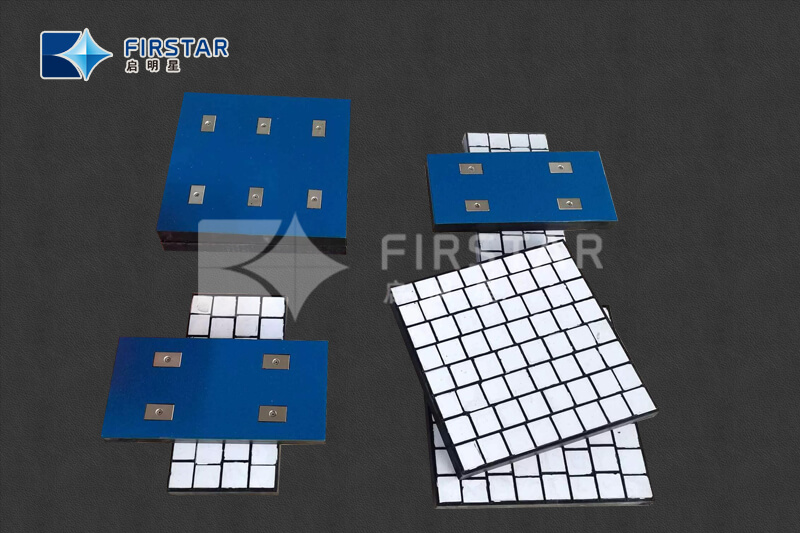

QMX will design and engineer ‘fit-for-purpose’ wear liner to achieve service longevity, predictable wear rates and liner layouts to suit the asset and application. Ceramic rubber wear liner is made from rubber or polyurethane, alumina ceramic tiles, and steel backing plate through the hot vulcanizing process. it is applied for bins, hoppers, chutes, etc Type of Ceramics:– High quality 92%, 95%, 99% alumina ceramic tiles, ZTA Tiles, RBSIC Silicon Carbide Tiles– 3-10mm steel backing plate (studded)– Durable Rubber protective coating– Superior bond strength (>6MPa)– Available in all shapes and sizesFeaturesBenefitsTwelve times more durable than Steel (proven by trials)Reduces cost of Annual Maintenance and Wear protection materialEnhanced service life at critical operating conditionsReduces shut down frequency, hence production costVarying shapes and thickness ceramicAppropriate selection possible to meet varying duty conditionsPredictable wear patternReduces production downtimeApplication: Product variants are selected based on the duty condition and the surface chosen for lining. This type of liners can be installed in chutes, launders, bins, feeders etc. where low to medium degree of impact resistance and very high degree of abrasion resistance is needed.Product ConstructionCeramic cylinder floating in rubber matrix with steel backing for tougher applications with larger material flow which contain some coarser material.Ceramic tiles of varying shapes and thickness with rubber and steel backing, ceramic wear plates have large and very hard ceramic locking tiles vulcanized into a matrix of wear resistant rubber.Ceramic tiles of varying thickness with rubber backing square ceramic tiles make it possible to bend the sheeting which makes it the perfect protection for both concave and convex surfaces.Ceramic tiles floating in rubber matrix with steel backing easy to fit to existing conveyors and will reduce material spillage giving longer belt and component life.

The pulverized coal system of the power plant includes three parts: raw material, pulverized coal and pulverized coal. The pipeline for conveying pulverized coal runs every day. It will not take long for the general metal composite pipeline to be worn through, resulting in powder leakage and affecting the normal operation of the power plant. We suggest the use of wear-resistant ceramic composite pipe, wear-resistant ceramic liner or ceramic pipe attached to the inner wall of the pipe, to form a strong wear-resistant layer, to resist the erosion and wear of coal powder.Because of the high wear resistance of wear-resistant ceramics, its Rockwell hardness is greater than 82HRA, Mohs hardness has reached grade 9, wear resistance is more than 10 times of high chromium cast iron material. And alumina ceramics have excellent corrosion resistance, can transport strong acid, alkali and other corrosive substances, can be widely used in chemical, metallurgy, steel, cement and other industries. Alumina ceramic composite pipe can effectively solve the problem of wear in power plant, prolong the service life of equipment more than 5 years, and ensure the safe operation of coal powder system in power plant.

REDUCE WEAR IN CRITICAL AREASAvailable in polyurethane and Alumina CeramicQuickly and easily installed into any pattern to help reduce wear in critical areas of your operation.Magnetic modular panels require no maintenanceNo welding, gluing or bolting necessaryOverall 35mm thick liner, perfect for covering holes in walls or chutesVulcanized with Polyurethane or Rubber Imbedded High strength rare earth magnets allow for installation using magnetic force alone No Bolting – No Welding – No Cutting to the applied area Eliminates the need for Hot Work permits in most areas Stay securely in place on vibrating screens and chutes Can be re-positioned easily and safely, when time permits, for the repair to be done permanently Can be field trimmed to fit unusual surfaces or conditions, due to the polyurethane material Custom Size Available Upon Request

ZTA Ceramic wear lining is designed to be extremely resistant to abrasion even in high material flows and speeds, preventing material build-up. It has proven to be valuable especially in wearing mining and aggregates applications. As a material, ceramic has beneficial anti-corrosion properties that prolong wear life and improve impact resistance. Ceramic lining also reduce noise and vibration.ItemHV Vickers hardness and fracture toughnessAverage hardnessHV10Average toughnessMPam-1/2Bulk densityg/cm3Wear resistancecm3AL2O3ZRO2ZTAHV101490151015261512154315165.884.250.020≥77%≥20%KIC5.895.896.126.065.72BENEFITSOptimized designCustomize your ceramic lining based on operating dataLong service-lifeCombinations of ceramics and other materials ensure extra-long life cycleSuperior qualityQMX production facilities have strict quality assurance to ensure high, uniform qualityMaximum wear life of your ceramic lining reduces the need for expensive downtime for maintenance work. Utilizing ceramic lining also tends to have a positive impact on working environment since resistant material cut down vibration and noise, and thus reduce risks and improve safety of personnel.Common applications for ceramic lining are:· Chute lining· Conveyor lining· Cyclone cluster lining· Hopper lining· Pipe lining· Pulley lining· Spout lining· Transfer point lining· To prevent material build-up in wet applications· Any other application subject to wearOptimized designQMX can tailor the specific ceramic tile size, shape, and layout of ceramic lining to meet the specific wear needs for your plant equipment.We can utilize the exact process data from your operations to design and manufacture a lining solution that meets your production targets. Long service-life – lower total costsIn many applications the optimal lining properties are a result of combining the best properties of other materials and ceramics.Combining different materials ensures an extra-long lifecycle in comparison with other wear protections. The extraordinarily hard ceramic elements provide unique resistance to sliding wear, while the elastic properties of other materials like rubber effectively absorb shock impacts.We can design and manufacture wear lining using ceramics, rubber, metal, polyurethane, and combinations of these materials. Superior qualityThe ceramic linings are produced in our own facilities applying strict quality assurance programs at every phase of research, development, design and production.This results in high, uniform quality for the entire supply. Precise dimensions and close tolerances ensure that your ceramic lining answer the required needs.