ZIRCONIUM TOUGHENED ALUMINA

ZTA - Aluminum Zirconium

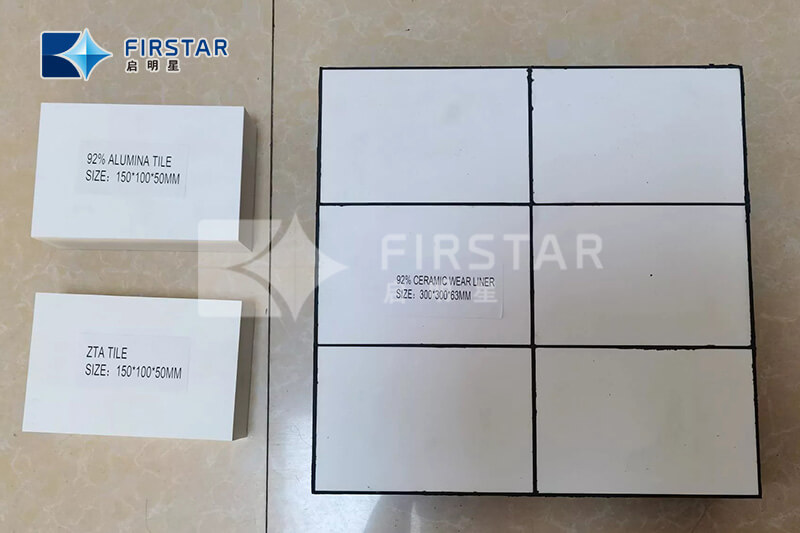

ZTA(Zirconia Toughened Alumina)Liners

Zirconia Toughened Alumina Ceramics also named ZTA ceramics, zirconium oxide

ceramics, which is white, corrosion resistance, chemical stability,a special combination of

aluminum oxide and zirconium oxide. QMX Ceramics technicians mix high purity alumina

with zirconia by the process of transformation toughening,making composite ceramic liner

more tougher,harder,wear resistance over alumina alone,and lower cost than zirconia.

Zirconia toughened alumina is a composite of alumina and zirconia which leads to an increase in strength and fracture toughness as compared to other aluminas.

INCREASED FRACTURE TOUGHNESS

The high fracture toughness gives it very good edge strength and makes the material ideal for components subjected to impact loading.

EXCELLENT WEAR RESISTANCE

During the sintering process, an extremely smooth microstructure is achieved which leads to superior wear performance.

GOOD THERMAL CONDUCTIVITY

ZTA materials provide for good dissipation of heat generated by friction.

Chemical composition:%

ZrO2: 20.8%

Al2O3: 76.8%

Physical properties:

Density: 4.216g/cm3

Compressive strength: 1150Mpa

Vikers Hardness HV10: 1481Mpa

Total Porosity: 1.6%

Fracture toughness(KIC (MPam-1/2): 3.5

Wear volume: 0.15cm3