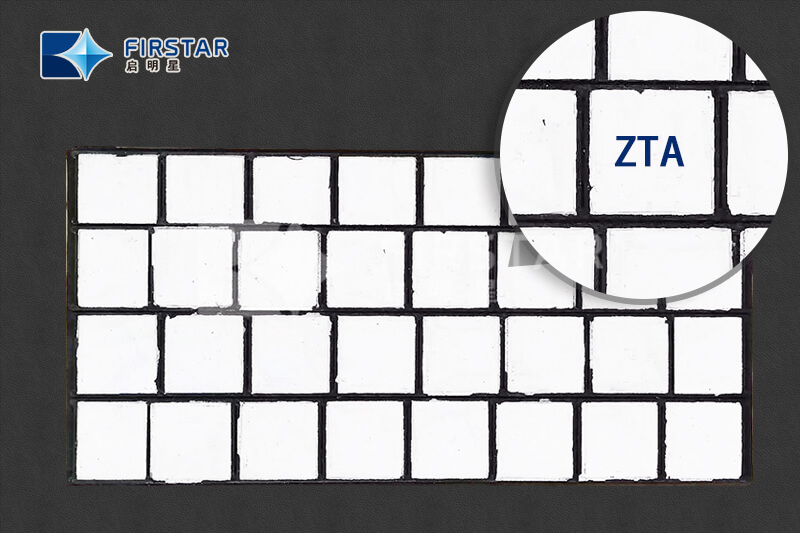

ZTA Ceramic wear lining is designed to be extremely resistant to abrasion even in high material flows and speeds, preventing material build-up. It has proven to be valuable especially in wearing mining and aggregates applications. As a material, ceramic has beneficial anti-corrosion properties that prolong wear life and improve impact resistance. Ceramic lining also reduce noise and vibration.

Item | HV Vickers hardness and fracture toughness | Average hardness HV10 | Average toughness MPam-1/2 | Bulk density g/cm3 | Wear resistance cm3 | AL2O3 | ZRO2 | |||||

| ZTA | HV10 | 1490 | 1510 | 1526 | 1512 | 1543 | 1516 | 5.88 | 4.25 | 0.020 | ≥77% | ≥20% |

KIC | 5.89 | 5.89 | 6.12 | 6.06 | 5.72 | |||||||

BENEFITS

Optimized design Customize your ceramic lining based on operating data |

Long service-life Combinations of ceramics and other materials ensure extra-long life cycle |

Superior quality QMX production facilities have strict quality assurance to ensure high, uniform quality |

Maximum wear life of your ceramic lining reduces the need for expensive downtime for maintenance work. Utilizing ceramic lining also tends to have a positive impact on working environment since resistant material cut down vibration and noise, and thus reduce risks and improve safety of personnel.

Common applications for ceramic lining are:

· Chute lining

· Conveyor lining

· Cyclone cluster lining

· Hopper lining

· Pipe lining

· Pulley lining

· Spout lining

· Transfer point lining

· To prevent material build-up in wet applications

· Any other application subject to wear

Optimized design

QMX can tailor the specific ceramic tile size, shape, and layout of ceramic lining to meet the specific wear needs for your plant equipment.

We can utilize the exact process data from your operations to design and manufacture a lining solution that meets your production targets.

Long service-life – lower total costs

In many applications the optimal lining properties are a result of combining the best properties of other materials and ceramics.

Combining different materials ensures an extra-long lifecycle in comparison with other wear protections. The extraordinarily hard ceramic elements provide unique resistance to sliding wear, while the elastic properties of other materials like rubber effectively absorb shock impacts.

We can design and manufacture wear lining using ceramics, rubber, metal, polyurethane, and combinations of these materials.

Superior quality

The ceramic linings are produced in our own facilities applying strict quality assurance programs at every phase of research, development, design and production.

This results in high, uniform quality for the entire supply. Precise dimensions and close tolerances ensure that your ceramic lining answer the required needs.