and Wear Resistant Products

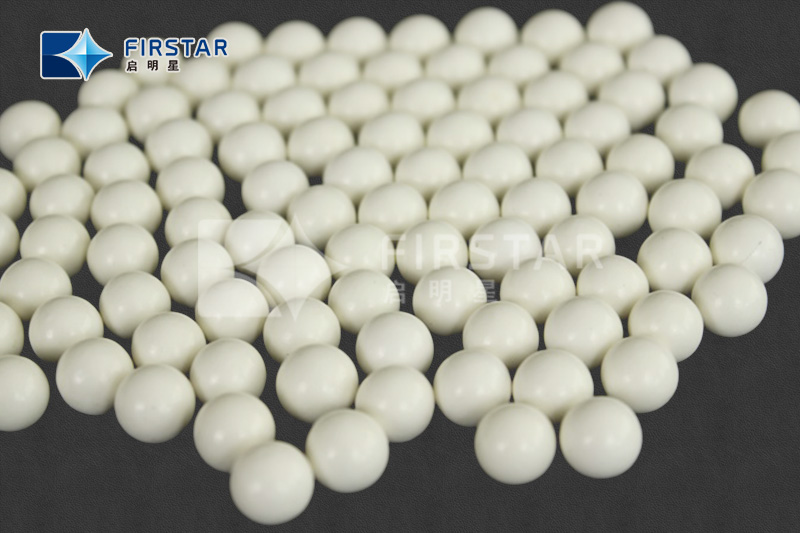

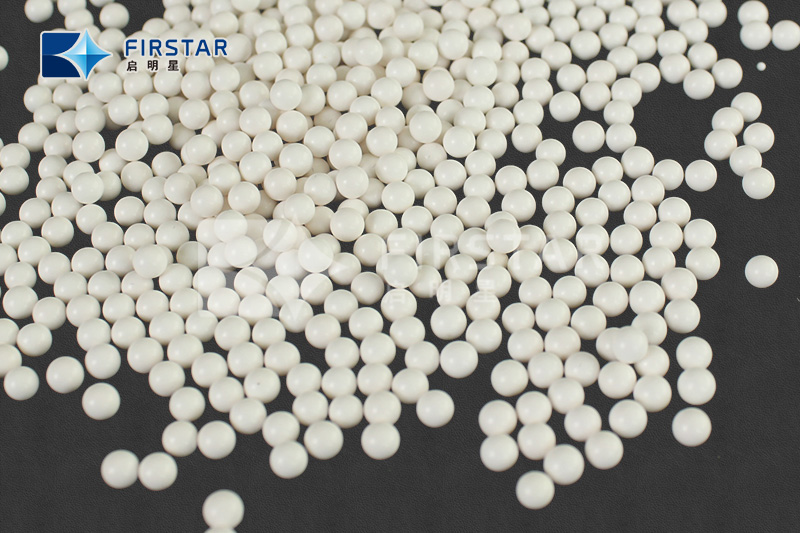

IMPROVE YOUR GRINDING EFFICIENCYQMX ceramic Grinding media products are engineered to provide superior strength, hardness, and uniform shape that result in high resistance to particle attrition and compressive breakdown. This results in less equipment wear during milling, reduces final product contamination, and lowers process costs.QMX ceramic grinding media is engineered to provide unmatched economic and performance advantages in ultra-fine grinding and regrind applications. The double sintering process used in manufacturing our media results in superior strength and wear resistance with consistent particle size and shape.The unique chemical composition of QMX Ceramic grinding media produces the durability and density that make it ideal for use in both vertical and horizontal mill operations. It is engineered to optimize grinding efficiency in the mill, reducing input energy. The light-colored media yields the desired finish when light color and brightness of the final product are critical.QMX Ceramic grinding media is engineered for uniform particle size and shape. This reduces wear on mechanical parts of milling equipment, resulting in lower maintenance costs and less downtime.FEATURES AND BENEFITSFEATURES• Superior strength and hardness• Uniform size and shape with excellentsphericity• Lower density than alternatives such assteel or iron balls• Exceptionally low internal porosity• Chemically inert and environmentallyfriendly• White color with high brightnessBENEFITS• High grind efficiency• Longer product life cycle• Decreases product contamination• Reduces equipment wear andmaintenance costsTypes of Ceramic Grinding QMX can manufactureALUMINA GRINDING MEDIA BALL Available Sizes: 0.5-30mm Sintering Rolling Type Ball 15-60mm Isostatic Pressed BallAlumina Content: 60%, 75%, 92%Density:2.8SG/3.2SG/3.6SG/3.70SGZTA(Zirconium Toughened Alumina Ball)Available Sizes: 0.5-13mm Sintering Rolling Type BallDensity:3.2~5.0 g/cm3 Zirconium Silicate Grinding Ball Available Sizes: 0.5-13mm Sintering Rolling Type BallDensity:4.1g/cm3 Yttria Zirconia Grinding Ball Available Sizes: 0.1-30mm Chemical Composition: 95% ZrO2,Density:6.1g/cm3 Ceria Zirconia Grinding Ball Available Sizes: 0.4-3.6mmChemical Composition: 80% ZrO2,Density:6.0g/cm3 Agate Grinding ballAvailable size: 3~ 30mmDensity: 2.65g/cm3PU(polyurethane) Grinding ballAvailable Size: 15mm,25mm,30mm

(1) ApplicationZTA grinding media, is mainly used in coating, paint, pigment, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, zirconia powder, mineral material, special chemical and other industries, also applied in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.(2) PropertiesHigh strength, high fracture toughness, high corrosion resistance and super smooth surface, etc.Large specific gravity, abrasion resistance, PPM abrasion grade, high hardness.(3)Chemical PropertyZTA280ZTA320ZTA370ZTA380ZTA450ZTA470Al2O3(%)≥57≥70≥87≥66≥5≥3ZrO2(%)≥5≥5≥5≥18≥62≥70SiO2(%)≤30≤20≤5≤12≤30≤24HV hardness(GPa)≥7≥8≥12.5≥11≥10≥10Crushing Strength(N)≥250(ø1.5-2)≥800(ø3.5)≥1000(ø3)≥12000(ø8)≥1200(ø3)≥1300(ø3)Water absorption<0.01<0.01<0.01<0.01<0.01<0.01Bulk density(g/cm3)≥2.80≥3.15≥3.70≥3.78≥4.48≥4.60Wear loss rate(g/kg.h)≤1.5≤1.5≤1.5≤1.5≤1.5≤1.5Sphericity≥95%≥95%≥95%≥95%≥95%≥95%(4) Standard Dimensionø0.5-1mm, ø1.5mm, ø2mm, ø2.5mm, ø3mm, ø3.5mm, ø4mm, ø5mm, ø6mm, ø8mm. 10mm,13mm(5) PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket

(1) ApplicationZTA grinding media, is mainly used in coating, paint, pigment, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, zirconia powder, mineral material, special chemical and other industries, also applied in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.)(2) PropertiesHigh strength, high fracture toughness, high corrosion resistance and super smooth surface, etc.Large specific gravity, abrasion resistance, PPM abrasion grade, high hardness.(3)Chemical PropertyZTA280ZTA320ZTA370ZTA380ZTA450ZTA470Al2O3(%)≥57≥70≥87≥66≥5≥3ZrO2(%)≥5≥5≥5≥18≥62≥70SiO2(%)≤30≤20≤5≤12≤30≤24HV hardness(GPa)≥7≥8≥12.5≥11≥10≥10Crushing Strength(N)≥250(ø1.5-2)≥800(ø3.5)≥1000(ø3)≥12000(ø8)≥1200(ø3)≥1300(ø3)Water absorption<0.01<0.01<0.01<0.01<0.01<0.01Bulk density(g/cm3)≥2.80≥3.15≥3.70≥3.78≥4.48≥4.60Wear loss rate(g/kg.h)≤1.5≤1.5≤1.5≤1.5≤1.5≤1.5Sphericity≥95%≥95%≥95%≥95%≥95%≥95%(4) Standard Dimensionø0.5-1mm, ø1.5mm, ø2mm, ø2.5mm, ø3mm, ø3.5mm, ø4mm, ø5mm, ø6mm, ø8mm. 10mm,13mm(5) PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket

Zirconium Toughened Alumina beads & balls are unique products, developed by our R&D team after several years of research and experiments. We adopt our experienced roll / granulation method for forming this type of products to make it specifically suitable for Mining wet grinding applications. Proved by many comparison wear rate tests, ZTA shows 4 - 30 times better in wear resistance than various quality High Alumina ( 90 - 92 % Al2O3 ) grinding media in global market, and its similar density enables this product to substitute High Alumina media very well. ■ZTA (ZrO2-Al2O3) Medium Density Ceramic Grinding Media Advantages: -Optimal density-Compatible with all mill types-No breakage of the grinding media-Higher milling efficiency-Low wear rate-Economic advantageApplications: High Tech ceramicsContamination free millingSpecial Products or raw materialpreparation- Technical ceramics --Pigments. Paints-Dielectric materials- Electro ceramics --Production of printing and inks-Piezoelectric materials- Refractory materials- Coatings- Magnetic Materials- Coating Materials- Paper industry- Minerals- Agro Chemicals Packing :1. 25kg/bag,40bags on 1 pallet (Plywood pallet)2. 1000kgs/jumbo bag, 1 bag packed on 1 pallet. (Plywood pallet)3. 2000kgs/jumbo bag, 1bag packed on 1 pallet. (plastic pallet) Delivery: The grinding media is delivered in container of 20’FCL.Storage: The grinding media should be stored in a dry and clean place.Support:Please do not hesitate to contact us if you need further technical information about milling processes or applications.