and Wear Resistant Products

What Is High Alumina Grinding ColumnAlumina grinding column refers to the high-temperature calcined Alpha alumina powder as raw material, through batching, grinding, powder making, molding, drying, firing, and other processesAlumina ceramic grinding columns make great ceramics, glasses, and enamels in chemical factories and other industries with ball mills, can-type mills, and vibration mills as their main machinery. Al2O3 Alumina grinding cylinder can also be used in these industries: metallic minerals, non-metallic minerals , silicon carbide, talcum, white pigments, cosmetics, cement, building materials.High Alumina Ceramic Grinding Column applicationsApart from grinding usages, you can form rubber-backed ceramic wear liners with our alumina grinding cylinders. The main application for Alumina Ceramic Column is within the mining industry.We suggest Al2O3 alumina grinding cylinders for stirred mills and ball mills preferably. Alumina grinding columns are widely used in different types of ceramics, enamels, glass, chemicals, etc. due to their excellent characteristics such as high strength, high hardness, high wear resistance, large specific volume, small volume, high-temperature resistance, and corrosion resistance.high Alumina Grinding Column advantageThe alumina grinding column has a grinding efficiency and abrasion resistance far exceeding ordinary ball stone and natural pebbles. It is an excellent grinding medium for fine grinding equipment such as ball mills, pot mills, and vibration mills.No abrasion, no corrosion, and no erosion. Alumina ceramic grinding columns resist almost everything. Acid, alkali, chips, extreme heat, and abrupt temperature changes, etc. Al2O3 Alumina grinding cylinder are also pollution-free, easy to clean, and 3-5 more durable than natural stone liners, and 23 times more durable than rubber liners. Installation and milling time are reduced at a minimum, while efficiency is augmented at a maximum.• Wear-resistant low loss• high-temperature resistance• corrosion resistance• High Mechanical StrengthHigh Al2O3 Alumina Ceramic Grinding cylinder specificationSpecification (mm)Diameter (mm)Height (mm)Φ15*151515Φ20*202020Φ25*252525Φ30*303030Alumina ceramic grinding Column Chemical Composition and Physical PropertiesAl2O3≥ 92%≥ 95%Fe2O3≤ 0.01%≤ 0.01%SiO2≤ 5.28%≤ 2.6%Na2O≤ 0.72%≤ 0.44%Hardness9 Mohs9 MohsWater Absorption≤ 0.01%≤ 0.01%Bulk Density≥ 3.6g/cm3≥ 3.7g/cm3Compression Strength≥ 2000 Mpa≥ 2500 MpaWear Loss≤ 0.001%≤ 0.0008%Note: As the grinding media, at a comparable weight with grinding balls, Al2O3 alumina ceramic grinding column have an approx.14% greater surface than alumina ceramic grinding ball.

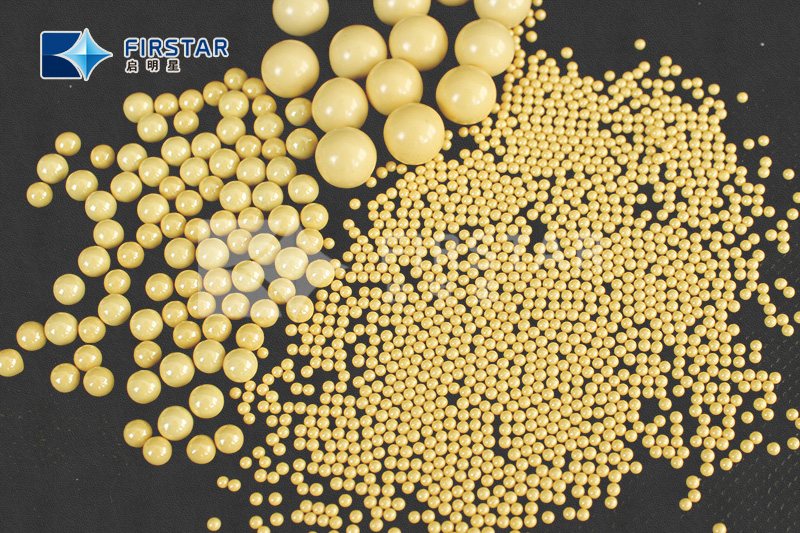

The grinding and finishing business requires the addition of media to achieve the right finish.It could be that you need smoother surfaces, or that you need to process corrosive materials.Whatever the case you have, including the appropriate zirconia ball media makes all the difference.When it comes to Ceria Stabilized Zirconia beads, you’ll notice that these are one of the more favored options.One of the main reasons for this is because they have an impressive lifespan.That’s regardless of the intensity of the process undertaken as your parts get finished.Experts estimate the longevity at up to 5 times what you would get from zirconium silicate beads and up to 30 times more than glass beads.They also show higher efficiency levels of up to 3 times better when compared with zirconium silicate bead media. What Are Cerium Stabilized Zirconia Beads?To make Ceria Stabilized Zirconia beads, you first require Ceria Stabilized Zirconia powder.The powder undergoes sintering to create the beads used for mass finishing processes.Sintering is necessary when dealing with powdered materials since it results in large solids without having to melt the compounds first.Ceria Stabilized Zirconia powder particles move across adjacent particle edges, helping them to fuse more compactly.It’s the same process natural minerals undergo below the earth’s surface to create the mineral deposits people mine.Sintering applies extreme heat and pressure to the Ceria Stabilized Zirconia powder producing the necessary bead media.The manufacturer makes that possible by including the desired mold to help shape out the right formations during the process.Including your shape mold ensures that the beads have the required dimensions.Once the process gets completed, the media won’t fall apart when being used to finish products.Ceria Stabilized Zirconia beads exhibit high levels of hardness and density due to proper sintering.Apart from that, the ultra-fine nature and structure of each homogenous tetragonal zirconia crystal guarantee the media also has low wear resistance.You can also get Ceria Stabilized Zirconia beads in a variety of colors, depending on their purpose.Some of the more commonly produced options are brown, white, silver, and grey, to list a few. These all have glossy finishes. Cerium Stabilized Zirconia Beads’ ApplicationsCeria Stabilized Zirconia beads come with properties such as high fracture toughness and strength.Add these to its smooth surface, and you have bead media that’s ideal for grinding high viscosity materials.These impressive qualities make it capable of completing the processing of different industry applications.A few examples of where you can use Ceria Stabilized Zirconia beads include the fact that:1. It can perform ultrafine grinding of high viscosity items. These include pastes such as paint, offset inks, and even screen printing inks.2. You can use it in the agrichemical field for the production of pesticides and aqueous agricultural chemicals.3. You can also use it with high strength products such as piezoelectric ceramics, dielectric ceramics, capacitors ceramics, and magnetic materials in the electrical industry.4. Ceria Stabilized Zirconia beads are used for milling CaCO3 and metals such as titanium dioxide.5. You can include these bead media in the production of dyes and pigments, such as those used in the textile industry.6. It’s used in food production, as well as in the medical and cosmetic industries.7. These beads can get applied to the papermaking process.8. You can use it with nanomaterials such as barium sulfate, lithium battery components such as lithium iron phosphate, as well as for grinding ceramic ink. Machines Work With Cerium Stabilized Zirconia BeadsThe parts you need to get finished require ideal processes to ensure the results are what you expected.Once you’re aware of the materials used to create your products, consider the process you need to undertake.Are you looking to polish the items or get an even surface for new production processes? With these and other milling processes, the size of your beads plays a significant role.You can have large, medium-sized, or tiny Ceria Stabilized Zirconia beads to enable the process.These include dimensions such as 0.5mm, 0.7mm, 1.0mm, 1.3mm, 1.5mm, and 2.0mm.In case you’re not sure what would work best, be sure first to get professional advice before you proceed.Using the wrong bead dimensions could wind up damaging your parts, instead of fixing them.That’s because one media bead size won’t automatically suit the finishing of different items.With all that information on hand, you’ll then be in a position to find the ideal machine to carry out the finishing.Due to their robust nature, Ceria Stabilized Zirconia beads work well with several milling machines.Their density helps to sustain high grinding kinetic energy for grinding efficiency.That’s especially when added to large capacity or high energy mills. You can add Ceria Stabilized Zirconia beads to milling machines like:· Horizontal Bead mills· High Speed Ultra Fine Mill· Vertical Attrition Mill· Ball Mill· Nano Mill· Vertical Bead Mill· Basket Mill· Planetary Ball mill· Horizontal Pin MillThe media’s impact resistance qualities keep your machines from requiring frequent maintenance.Media that breaks apart could easily get stuck in the mill’s moving parts, causing damage to the milling machine as well as the parts you’re finishing. SummaryMany finishing companies tend to create their finishing media rather than purchasing from other companies.That’s because they’re aware of the types of media they require to keep their plants operational. Small scale plants will, however, purchase from more established manufacturers.As such, you can receive all the necessary information on Ceria Stabilized Zirconia to help you get the job done.The best part about dealing with seasoned professionals is they’re aware of the industry’s best practices.Therefore, if you’re just getting started in the mass finishing business, at Inovatec, you have people who can make the process smooth for you from the beginning.Ceria Stabilized Zirconia beads are one of the few media that can withstand extreme finishing processes for extended periods.Therefore, if you would like to use it for any of the mentioned applications, you’re now aware of what the results of the finishing process will be.DescriptionProperties ShapeSphericalCompositionZirconium 80%+Ceria 20%ColorMarigoldSize0.4-10mmDescriptionProperties Specific Density5.9~6.2gr/cm3(kg/dm3)Bulk Density3.6~3.8gr/cm3(kg/dm3)HV Hardness1150

Ceramic Media that’s Rounder, Stronger and Longer LastingImagine what you can achieve with the right grinding media in your bead mill.With QMX Zirconium Oxide Grinding Media, you can discover how simple and easy it is to keep your mills healthy and unleash the untapped potential in your bead milling process.QMX Zirconium Oxide Grinding Media is chemically inert and non-toxic.This ceramic media is non-magnetic, and is proven to increase flow rates and improve particle dispersion.There are many things that set this ceramic grinding media apart from other ceramic milling media. One reason they are so unique, is their microstructure.These ceramic balls are made from a combination of tough, high strength, Tetragonal Zirconia Polycrystal (TZP) materials. These tighter micro-structures enhance wear resistance in the grinding media.They’re even denser, harder, tougher, and more wear resistant than QMX Zirconium Silicate grinding balls, and that’s saying a lot!Up to 3 times more wear resistant…Application:- Electronic Industry1. Iron and chrome based magnetic materials( For audio, Video, recording taples) and other magnetic materials2. Piezoelectric materials, dielectric materials(for high purity grinding where the media should not discolour the mix being ground or cause any impurity due to wearing of the media).3. Electronic grade ceramics(ferroelectric, piezoelectic, dielectric, capacitors, sensors, etc.)4. Micro beads are suitalbe for processing of materials of multi-layer ceramic capacitors(MLCCS).5. Electronic materials(LCD color paste, PDP glass paste, CMP slurry etc.)6. Battery raw materials- Cosmetic Industry1. Fine Grinding of pigments and solids for lipsticks, skin and sun protection creams.2. Processing of face powders, liquid make-ups3. Others cosmetics and toiletries- Mineral Industry1. Aluminium Hydroxide2. Rare-earth materials and other minerals- Paper IndustryProcess of whitener(CaCo3) for the paper production.- Food Industry1. It is used in food industry due to its lack of contamination to in the materials being ground2. Chocolate producing DescriptionProperties Shape SphericalCompositionZirconium 80%+Ceria 20%ColorMarigoldSize0.4-10mm DescriptionProperties Specific Density5.9~6.2gr/cm3(kg/dm3)Bulk Density3.6~3.8gr/cm3(kg/dm3)HV Hardness1150

Yttria stabilized zirconia(YTZP) is a sintered advanced ceramic material and it is the most common form of stabilized zirconia ceramic. Typical composition of Yttria Stabilized Zirconia is 94.7% ZrO2 + 5.2% Y2O3(weight percentage) or 97 ZrO2 + 3% Y2O3 (mol percentage)Compared with alumina rod Yttria stabilized zirconia (YSZ YTZP) rods could withstand even higher temperature. Zirconia also has better corrosion and wearing resistance. As an extremely refractory material, working temperature of zirconia rods could be as high as 1900C and being stable to most of corrosive chemicals as well. Zirconia crucibles also provide very low thermal and electrical conductivity amking it an ideal for applications requires electrical and thermal insulatingHowever, unlike boron nitride, Zirconia rod is not recommended to be used as a raw material for further machining work, due to the high hardness and wearing resistance.QMX YSZ RodsAs a major supplier of custom advance ceramic materials in east coast USA, QS Advanced Materials is working closely with manufacturers of ceramic sintering and machining capability to provide quality stabilized zirconia products with highly efficient price. We are continuously providing zirconia crucibles and other basic materials. With semi finished stocks, and high production capbalility, advantages in lead time and cost is provided.Applications of Yttria Stabilized Zirconia (YSZ,YTZP) parts• Used for grinding ceramics materials, magnetic materials and organic samples• Bearing and other wear resistance mechanical parts• Special pump partsZirconia ceramics performance:Density: 6.05 g/cm3Water absorption: <0.05%Firing temperature: 1550 °CHardness: 1350 HVCompression strength: 25000 MPaThermal expansion coefficient: 9.5x10-6 /°CBending strength: 950 MPa PackagingAs a ceramic material, Zirconia material is still brittle, although YSZ is somehow flexible. Our zirconia rods are usually hold in plastic bags by vacuum, and protect with heavy foam. Properties Sheet:PropertiesUnits95 Alumina99 AluminaZirconiaDensityɡ / cm33.653.925.95-6.0Water Absorption%0010Coefficient of Thermal Expansion10-6 / K7.98.510.5HV HardnessMpa140016501300-1365Flexural Strength @ Room TemperatureMpa280310950Flexural Strength @ 700℃Mpa220230210Compressive Strength@Room TemperatureMpa200022002000Fracture ToughnessMpa * m½3.84.210Heat Conductivity @ Room TemperatureW / m * k18-2526-302.0-2.2Electrical Resistivity @ Room TemperatureΩ*mm2 / m>1015>1016>1015Max Application Temperature℃150017501050Resistance to Acid Alkaline/HighHighHighDielectric Constant/9.59.826Thermal Shock ResistanceΔ T ( ℃ )220180-200282-350Tensile Strength @ 25℃Mpa200248252

◆Product IntrductionZirconia Y-TZP cylinder media is made from super material and advanced technical craft and suitable for any kinds of mills such as micro-mill, attritor-mill, vibratory mill and bead mill to grind and disperse effectively and economically the material of electronic slurry, ceramic powder, magnetic material, battery material, rare-earth material, nonmetal ore, painting, dye, ink, calcium, titanium, pesticide, food stuff and medicine etc.Comparing with other grinding media such as Alumina media, zirconia silicate media, steel media, agate media and glass media, Zirconia Y-TZP grinding media has high density and toughness and super hardness, so it has better grinding efficiencies. The high wear-resistant Zirconia Y-TZP grinding media prevents materials from being contaminated and chemical etching or short service life of the grinder.These special features make Zirconia Y-TZP grinding media especially suitable for material grinding in important occasion. ◆Product Features▮Product Features Preventing material from contamination▮High grinding efficiency▮Suitable for high viscosity, wet grinding and dispersion▮So it's tougher and more resistant to wear and deterioration from a long term point of view. ◆Zirconia Y-TZP Ceramic Balls PropertiesItemsUnitTypical ValuesCompositionwt%94.8% ZrO2 5.2%Y2O3Bulk Densitykg/L3.5 (Ф>7mm)Specific Densityg/cm36.0Hardness(HV)GPa>12Modulus of ElasticityGPa200Thermal ConductivityW/m.K3Thermal Expansion Coefficient10×10-6/°C(20to400)9.6Crushing LoadKN≥25(Ф7mm)Fracture ToughnessMPam½8Grain Sizeµm≤0.5◆Applications and Specifications▮High strength and high toughness productsDiectricity materials、Piezoelectric materials、Magnetic materials▮Wear and corrosion resistance productsCoating、Textile、 Pigment dispersion、Ink and dye▮Prevention of product Ceramics contaminationMedical material、Foodstuffs▮CeramicsElectronics ceramics、Refractory ceramics、Engineer ceramics◆Available Sizes▮Zirconia Y- TZP Cylindrical Media are available in the following standard sizes:Ф5.5×5.5、Ф7.5x7.5, Ф7.5x9、Ф10x10, Ф12.7×12.7、Ф15×15(mm)

IMPROVE YOUR GRINDING EFFICIENCYQMX ceramic Grinding media products are engineered to provide superior strength, hardness, and uniform shape that result in high resistance to particle attrition and compressive breakdown. This results in less equipment wear during milling, reduces final product contamination, and lowers process costs.QMX ceramic grinding media is engineered to provide unmatched economic and performance advantages in ultra-fine grinding and regrind applications. The double sintering process used in manufacturing our media results in superior strength and wear resistance with consistent particle size and shape.The unique chemical composition of QMX Ceramic grinding media produces the durability and density that make it ideal for use in both vertical and horizontal mill operations. It is engineered to optimize grinding efficiency in the mill, reducing input energy. The light-colored media yields the desired finish when light color and brightness of the final product are critical.QMX Ceramic grinding media is engineered for uniform particle size and shape. This reduces wear on mechanical parts of milling equipment, resulting in lower maintenance costs and less downtime.FEATURES AND BENEFITSFEATURES• Superior strength and hardness• Uniform size and shape with excellentsphericity• Lower density than alternatives such assteel or iron balls• Exceptionally low internal porosity• Chemically inert and environmentallyfriendly• White color with high brightnessBENEFITS• High grind efficiency• Longer product life cycle• Decreases product contamination• Reduces equipment wear andmaintenance costsTypes of Ceramic Grinding QMX can manufactureALUMINA GRINDING MEDIA BALL Available Sizes: 0.5-30mm Sintering Rolling Type Ball 15-60mm Isostatic Pressed BallAlumina Content: 60%, 75%, 92%Density:2.8SG/3.2SG/3.6SG/3.70SGZTA(Zirconium Toughened Alumina Ball)Available Sizes: 0.5-13mm Sintering Rolling Type BallDensity:3.2~5.0 g/cm3 Zirconium Silicate Grinding Ball Available Sizes: 0.5-13mm Sintering Rolling Type BallDensity:4.1g/cm3 Yttria Zirconia Grinding Ball Available Sizes: 0.1-30mm Chemical Composition: 95% ZrO2,Density:6.1g/cm3 Ceria Zirconia Grinding Ball Available Sizes: 0.4-3.6mmChemical Composition: 80% ZrO2,Density:6.0g/cm3 Agate Grinding ballAvailable size: 3~ 30mmDensity: 2.65g/cm3PU(polyurethane) Grinding ballAvailable Size: 15mm,25mm,30mm

Ceria Stabilized Zirconia Grinding MediaIt is suitable for large capacity vertical mills for dispersion of CaCO3.It is suitable for high-efficiency horizontal mills.It is suitable for the production of high-viscosity paints and inks.It has high wear-resistance and a bright brown color, so there is no contamination caused by thecolor of beads. It is being used for TiO2 makers that require a true white color.It has high grinding efficiency, making it suitable for aqueous agricultural chemicals.It is suitable for the production of pigments and dyes.3.Chemical PropertyChemical Composition and Physical PropertiesCompositionZr020.8CeO30.2Bulk Density5.98~6.05g/cm3Packing Density≥ 3.90HV Hardness(GPa)≥ 11Standard Size0.4-6.0mmSphericity≥ 95Packing25Kgs4.Standard DimensionØ0.4-6.0mm5. PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket

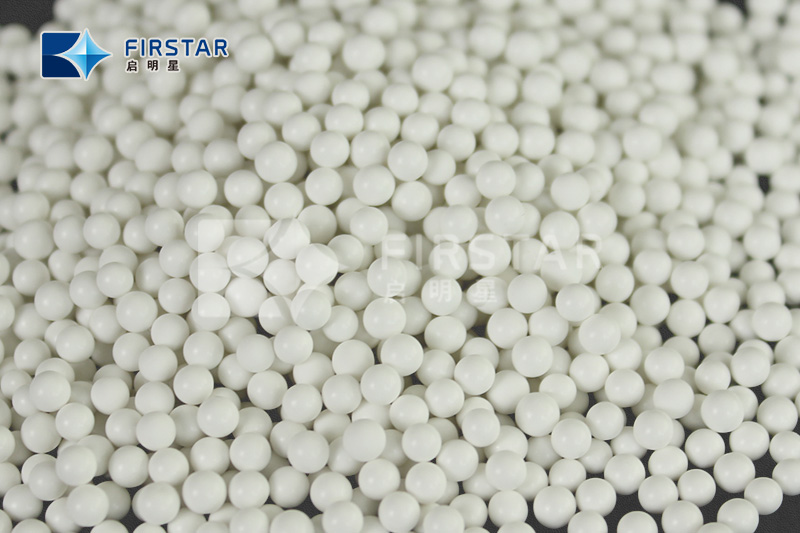

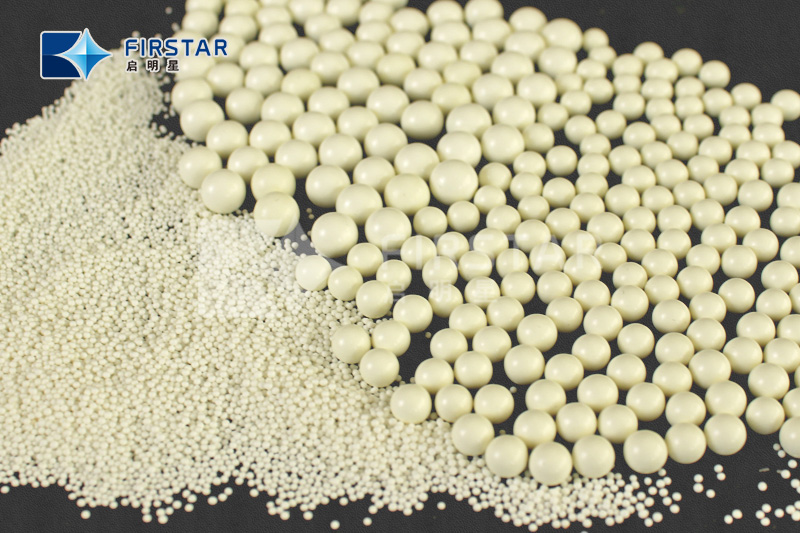

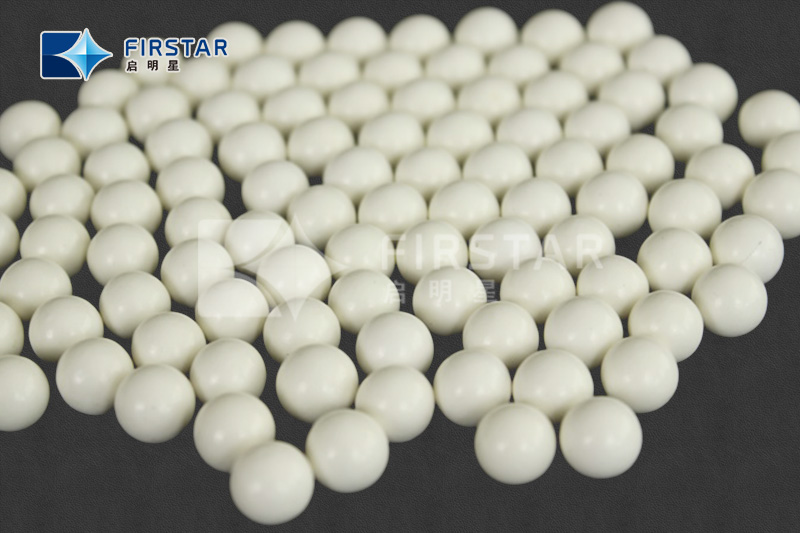

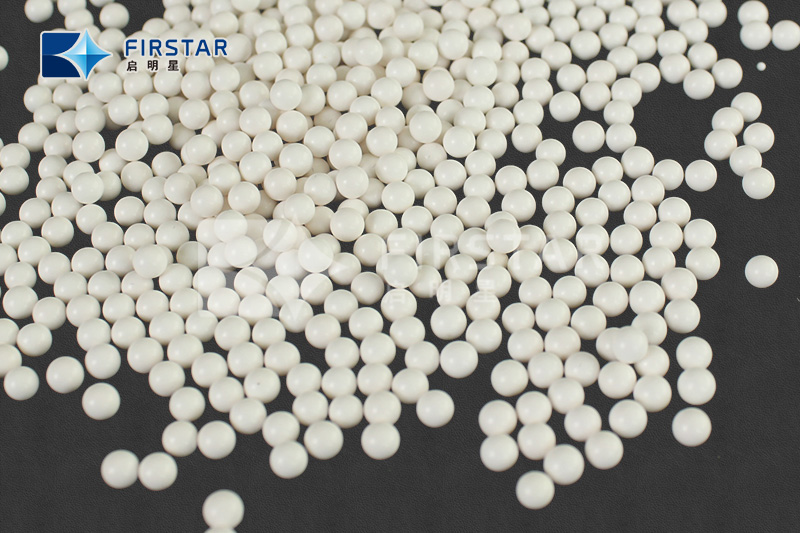

(1) ApplicationAlumina grinding media ball is mainly used in ceramic, glaze, paint, zirconia silicate, aluminum oxide, quartz, silicon carbide, talc, lime carbonate, kaolin, titanium and other materials grinding, and mechanical equipment accessories.(2) PropertiesHigh density, high hardness, low wear loss, regular shape, impact resistance, corrosion resistance, etc.(3) Chemical Property92% Alumina Grinding BallAl2O3(%)92±1Fe2O3(%)<0.25SiO2(%)≤5Mohs hardness9Water absorption<0.01Bulk density(g/cm3)>3.60Wear loss(g/kgh)<1.6Crushing strength(3mm)>1050NSizeØ0.5-60mmSphericity>95%75% Alumina Grinding BallAl2O3(%)>75Fe2O3(%)<0.4SiO2(%)≤20Mohs hardness8Water absorption<0.01Bulk density(g/cm3)>3.15Wear loss(g/kgh)<1.6Crushing strength(3mm)>800NSizeØ0.5-13mmSphericity>95%60% Alumina Grinding BallAl2O3(%)≥60Fe2O3(%)<0.6SiO2(%)≤31Mohs hardness7Water absorption<0.01Bulk density(g/cm3)>2.8Wear loss(g/kgh)<1.6Crushing strength(3mm)>600NSizeØ0.5-13mmSphericity>95%99% Alumina Grinding BallAl2O3(%)≥99Others(%)<0.5Mohs hardness7Water absorption<0.01Bulk density(g/cm3)>3.90Wear loss(g/kgh)<1.6Crushing strength(30mm)>55000NSizeØ0.5-13mmSphericity>95%(4) Standard Dimensionø0.5-1mm, ø1.5mm, ø2mm, ø2.5mm, ø3mm, ø3.5mm, ø4mm, ø5mm, ø6mm, ø8mm, ø10mm, ø13mm,ø15mm, ø20mm, ø30mm, ø40mm, ø50mm, ø60mm(5) PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing

This alumina grinding media possesses excellent thermal properties. So you can grind down to the particle size you need to achieve.Better for some applications than porcelain, flint pebbles, or natural stones, Ultraming Alumina grinding balls are precisely engineered, down to the nanometer.Because when it comes to your ball milling process, every nanometer counts.DESCRIPTIONPROPERTIESShapeSpherical, cylindricalColorWhiteAlumina60%, 75%, 92%Ball size0.5-30 Rolling Type25-60mm Pressed TypeHardness7-9MohsSelf Wear Rate≤0.08g/kg.h

-High density-High fracture toughness-Large Specific density-Wear resistant,anti corrosion-PPM Grade wear loss Applications:-Suitable for Electronic ceramic,ink,paint,pigments,coating,dyes,food,cosmetic,pharmaceutical industry which require high wear resistance and contamination-free from grinding media-Suitable for fine particle size production as high compression strength and narrow size distribution- Suitable for nano particle size production industry. Chemical PropertyYTZ yttria zirconia grinding beads propertiesItemsTypical ValuesCompositionWt%94.8% ZrO25.2% Y2O3Packing Densitykg/L3.7~3.9Bulk Densityg/cm35.95~6.0Hardness (HV)GPa>8Wear loss(g/kgh)≤1.3Crushing StrengthN(⌀5)≥16000Sphericity%≥95Standard sizemm0.3-30Packing25kgsPackageDifferent package as to meet different customer’s requirements.25kg/pails+Wooden Crates

-High density-High fracture toughness-Large Specific density-Wear resistant,anti corrosion-PPM Grade wear loss Applications:-Suitable for Electronic ceramic,ink,paint,pigments,coating,dyes,food,cosmetic,pharmaceutical industry which require high wear resistance and contamination-free from grinding media-Suitable for fine particle size production as high compression strength and narrow size distribution- Suitable for nano particle size production industry. Chemical PropertyYTZ yttria zirconia grinding beads propertiesItemsTypical ValuesCompositionWt%94.8% ZrO25.2% Y2O3Packing Densitykg/L3.7~3.9Bulk Densityg/cm35.95~6.0Hardness (HV)GPa>8Wear loss(g/kgh)≤1.3Crushing StrengthN(⌀5)≥16000Sphericity%≥95Standard sizemm0.3-30Packing25kgsPackageDifferent package as to meet different customer’s requirements.25kg/pails+Wooden Crates

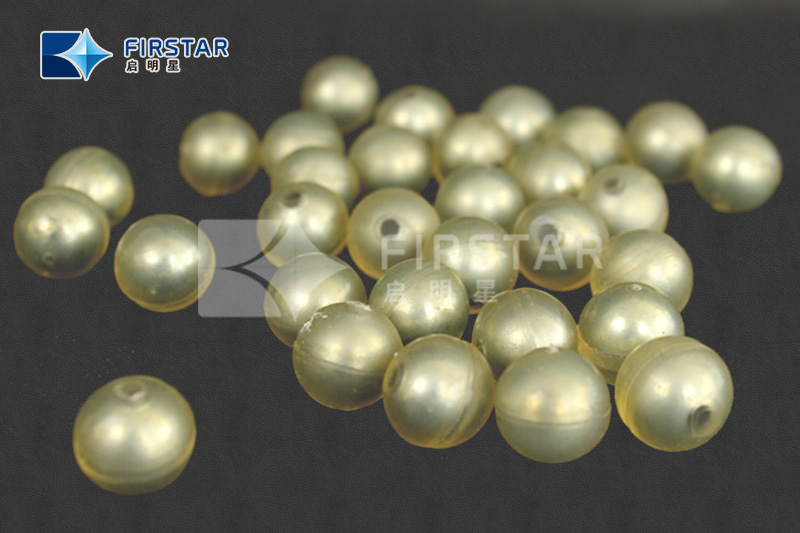

Agate grinding media is made by the original natural agate ore after grinding, polishing and processing. Its hardness is >7, diameter size is ±1mm, the content of silicon dioxide is >97%. Mainly used for electronic material. high purity alumina and new materials’ grinding.Chemical Composition and Physical PropertiesMain CompositionAgtae-Sio2Main CompositionDensity2.65/cm3DensityWhiteIvory white or GreyWhiteHardness7.2-7.5MohsHardnessAbrasion resistanceGoodAbrasion resistanceShapeSphereShapeStandard Size5-8mm/6-6.5mm/10-15mm/15-25mm/25-38mmStandard SizeCompatible Ball Mill JarsAgate milling JarCompatible Ball Mill Jars

PU grinding mediaPolyurethane ball is zero pollution medium ball which purchased by part of the specific high-tech enterprise. Our company adopts the special processing technology to ensure the concentricity of the inner metal ball and outer polyurethane lining, greatly improved its service life, and safety character. Now it is widely used in the grinding and mixing of all kinds high grade materials.Our company can make various kinds of ceramic grinding media professional, is a high and new technology enterprise, has passed ISO9001 quality system certificate, can make high wear resistance and high strength aluminum zirconium silicate composite beads, and other production process, we has a patent for invention, production,received extensive recognition and application at home and abroad.Our product, include all kinds of grinding media(zirconia bead, alumina bead, zirconia silicate bead, ZTA bead) is mainly used in coating, paint, printing ink, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, special chemical and other industries, zirconia bead, mainly used in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.)Specific Density 11.3kg/LTear Strength40-100KN/mShore A Hardness35-95Tensile Strength30-50MPaAkron abrasion<0.053(CM3/1.61km)Deformation<8%Working Temperature-25-80℃Insulation StrengthExcellentExpansion strength70KN/mGrease resistantExcellent

Zirconium Silicate (ZS)Grinding BeadUltraming ZR-400 Ceramic Beads are specially designed for superfine grinding mills with high speed and energy input.Ultraming ZR-400 Ceramic Beads are ideal combination of high grinding efficiency and low wear rate. It can be widely used in energy intensive mills.Application:1. Metallic minerals like Copper, Silver, Nickel, Gold, Zinc, PGM, Lead, etc.2. Non-metallic minerals like Graphite, Calcium Carbonate, Kaolin Clay, Zirconium Silicate, Titanium Dioxide, Gypsum and Quartz, etc.3. Advanced Ceramic Materials, Frits and Glazes.4. Chemical Material, Paint, Pigment, Printing Ink, Dye. Specification:Densityg/cm3> 4.0Packing densityg/cm3> 2.4Vickers HardnessKgf/mm21,000 – 1,050Roundness%> 95Standard size*mm0.5-13Chemical compositioAl2O3, ZrO2, SiO2 and others* Other sizes are available upon requestPackaging:Standard: Net 1,000 KG in 1 Jumbo bag, 2 bags packed on 1 pallet, 20MT/20’FCL

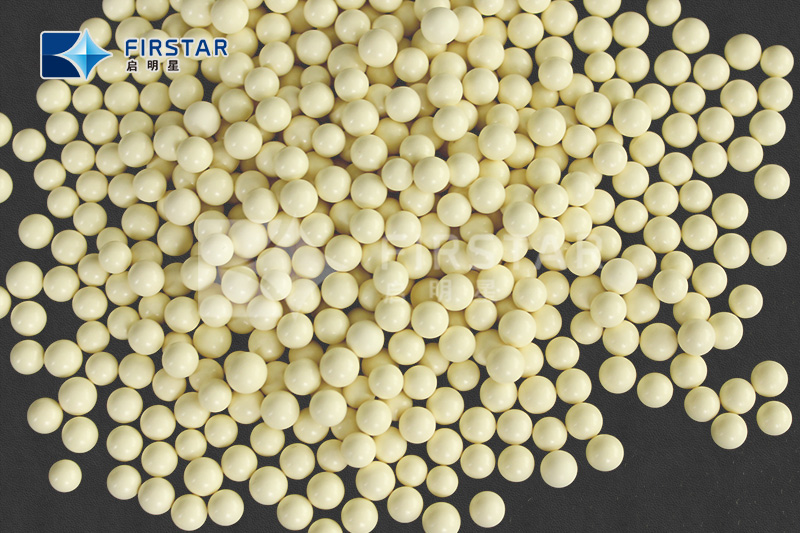

1.ApplicationZirconia silicate grinding media, is mainly used in coating, paint, pigment, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, zirconia powder, mineral material, special chemical and other industries, also applied in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.)2. PropertiesHigh strength, high fracture toughness, high corrosion resistance and super smooth surface, etc.Large specific gravity, abrasion resistance, PPM abrasion grade, high hardness.3.Chemical PropertyZrO2(%)≥50AL2O3(%)≤16SiO2(%)≤30HV hardness(HV5)≥9.5GPaWater absorption<0.01Bulk density(g/cm3)>4.08Wear loss(g/kg.h)<1.2SizeØ0.5-13mmSphericity≥95%ColorIvory White4. Standard DimensionØ0.5mm-13mm5.PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket

(1) ApplicationZTA grinding media, is mainly used in coating, paint, pigment, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, zirconia powder, mineral material, special chemical and other industries, also applied in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.(2) PropertiesHigh strength, high fracture toughness, high corrosion resistance and super smooth surface, etc.Large specific gravity, abrasion resistance, PPM abrasion grade, high hardness.(3)Chemical PropertyZTA280ZTA320ZTA370ZTA380ZTA450ZTA470Al2O3(%)≥57≥70≥87≥66≥5≥3ZrO2(%)≥5≥5≥5≥18≥62≥70SiO2(%)≤30≤20≤5≤12≤30≤24HV hardness(GPa)≥7≥8≥12.5≥11≥10≥10Crushing Strength(N)≥250(ø1.5-2)≥800(ø3.5)≥1000(ø3)≥12000(ø8)≥1200(ø3)≥1300(ø3)Water absorption<0.01<0.01<0.01<0.01<0.01<0.01Bulk density(g/cm3)≥2.80≥3.15≥3.70≥3.78≥4.48≥4.60Wear loss rate(g/kg.h)≤1.5≤1.5≤1.5≤1.5≤1.5≤1.5Sphericity≥95%≥95%≥95%≥95%≥95%≥95%(4) Standard Dimensionø0.5-1mm, ø1.5mm, ø2mm, ø2.5mm, ø3mm, ø3.5mm, ø4mm, ø5mm, ø6mm, ø8mm. 10mm,13mm(5) PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket

(1) ApplicationZTA grinding media, is mainly used in coating, paint, pigment, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, zirconia powder, mineral material, special chemical and other industries, also applied in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.)(2) PropertiesHigh strength, high fracture toughness, high corrosion resistance and super smooth surface, etc.Large specific gravity, abrasion resistance, PPM abrasion grade, high hardness.(3)Chemical PropertyZTA280ZTA320ZTA370ZTA380ZTA450ZTA470Al2O3(%)≥57≥70≥87≥66≥5≥3ZrO2(%)≥5≥5≥5≥18≥62≥70SiO2(%)≤30≤20≤5≤12≤30≤24HV hardness(GPa)≥7≥8≥12.5≥11≥10≥10Crushing Strength(N)≥250(ø1.5-2)≥800(ø3.5)≥1000(ø3)≥12000(ø8)≥1200(ø3)≥1300(ø3)Water absorption<0.01<0.01<0.01<0.01<0.01<0.01Bulk density(g/cm3)≥2.80≥3.15≥3.70≥3.78≥4.48≥4.60Wear loss rate(g/kg.h)≤1.5≤1.5≤1.5≤1.5≤1.5≤1.5Sphericity≥95%≥95%≥95%≥95%≥95%≥95%(4) Standard Dimensionø0.5-1mm, ø1.5mm, ø2mm, ø2.5mm, ø3mm, ø3.5mm, ø4mm, ø5mm, ø6mm, ø8mm. 10mm,13mm(5) PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing Plastic Bucket

Zirconium Toughened Alumina beads & balls are unique products, developed by our R&D team after several years of research and experiments. We adopt our experienced roll / granulation method for forming this type of products to make it specifically suitable for Mining wet grinding applications. Proved by many comparison wear rate tests, ZTA shows 4 - 30 times better in wear resistance than various quality High Alumina ( 90 - 92 % Al2O3 ) grinding media in global market, and its similar density enables this product to substitute High Alumina media very well. ■ZTA (ZrO2-Al2O3) Medium Density Ceramic Grinding Media Advantages: -Optimal density-Compatible with all mill types-No breakage of the grinding media-Higher milling efficiency-Low wear rate-Economic advantageApplications: High Tech ceramicsContamination free millingSpecial Products or raw materialpreparation- Technical ceramics --Pigments. Paints-Dielectric materials- Electro ceramics --Production of printing and inks-Piezoelectric materials- Refractory materials- Coatings- Magnetic Materials- Coating Materials- Paper industry- Minerals- Agro Chemicals Packing :1. 25kg/bag,40bags on 1 pallet (Plywood pallet)2. 1000kgs/jumbo bag, 1 bag packed on 1 pallet. (Plywood pallet)3. 2000kgs/jumbo bag, 1bag packed on 1 pallet. (plastic pallet) Delivery: The grinding media is delivered in container of 20’FCL.Storage: The grinding media should be stored in a dry and clean place.Support:Please do not hesitate to contact us if you need further technical information about milling processes or applications.