IMPROVE YOUR GRINDING EFFICIENCY

QMX ceramic Grinding media products are engineered to provide superior strength, hardness, and uniform shape that result in high resistance to particle attrition and compressive breakdown. This results in less equipment wear during milling, reduces final product contamination, and lowers process costs.

QMX ceramic grinding media is engineered to provide unmatched economic and performance advantages in ultra-fine grinding and regrind applications. The double sintering process used in manufacturing our media results in superior strength and wear resistance with consistent particle size and shape.

The unique chemical composition of QMX Ceramic grinding media produces the durability and density that make it ideal for use in both vertical and horizontal mill operations. It is engineered to optimize grinding efficiency in the mill, reducing input energy. The light-colored media yields the desired finish when light color and brightness of the final product are critical.

QMX Ceramic grinding media is engineered for uniform particle size and shape. This reduces wear on mechanical parts of milling equipment, resulting in lower maintenance costs and less downtime.

FEATURES AND BENEFITS FEATURES • Superior strength and hardness | BENEFITS • High grind efficiency |

Types of Ceramic Grinding QMX can manufacture

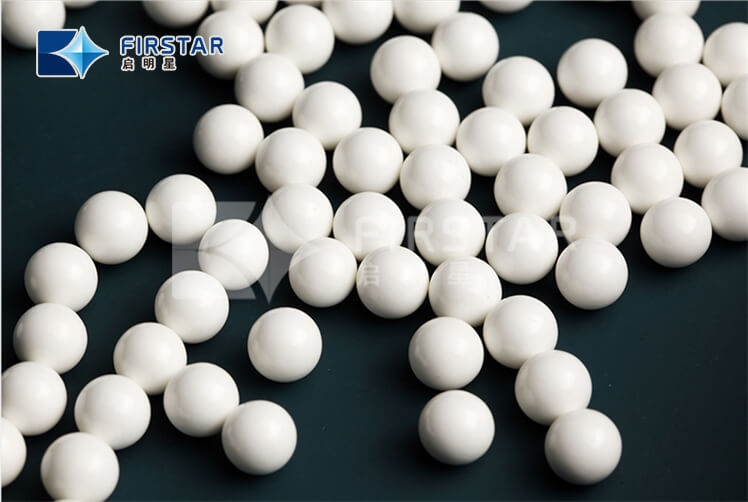

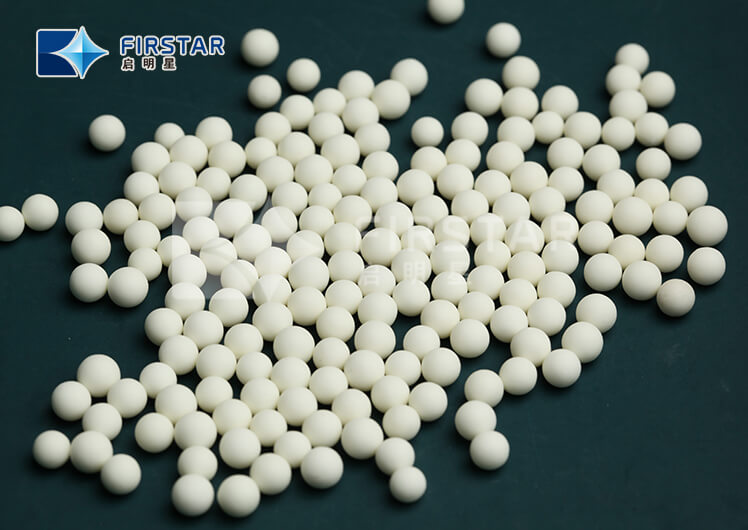

ALUMINA GRINDING MEDIA BALL Available Sizes: 0.5-30mm Sintering Rolling Type Ball 15-60mm Isostatic Pressed Ball Alumina Content: 60%, 75%, 92% Density:2.8SG/3.2SG/3.6SG/3.70SG |  |

ZTA(Zirconium Toughened Alumina Ball) Available Sizes: 0.5-13mm Sintering Rolling Type Ball Density:3.2~5.0 g/cm3 |  |

Zirconium Silicate Grinding Ball Available Sizes: 0.5-13mm Sintering Rolling Type Ball Density:4.1g/cm3 |  |

Yttria Zirconia Grinding Ball Available Sizes: 0.1-30mm Chemical Composition: 95% ZrO2, Density:6.1g/cm3 |  |

Ceria Zirconia Grinding Ball Available Sizes: 0.4-3.6mm Chemical Composition: 80% ZrO2, Density:6.0g/cm3 |  |

Agate Grinding ball Available size: 3~ 30mm Density: 2.65g/cm3 |  |

PU(polyurethane) Grinding ball Available Size: 15mm,25mm,30mm |  |

Mining Ceramic Grinding Media

Mining Ceramic Grinding Media