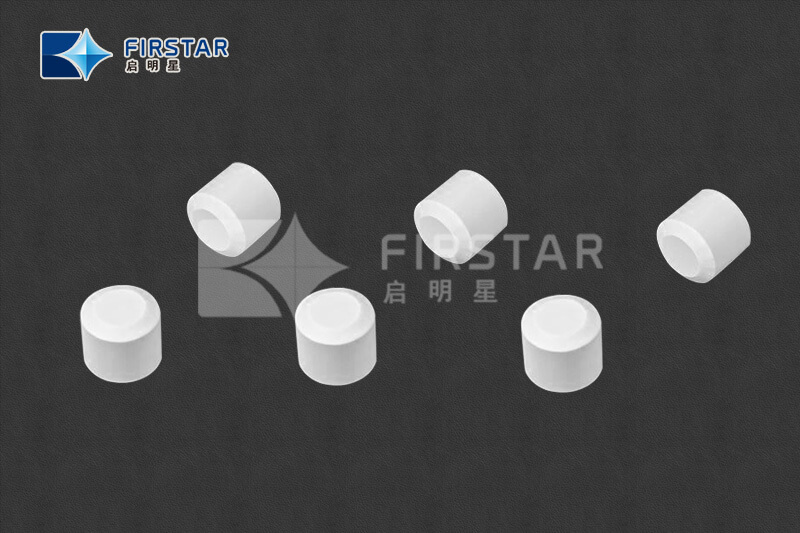

Alubit High Alumina ceramic Grinding Cylinder is used as grinding media for ceramic body and glaze preparation. It’s high purity and low abrasion loss make it to be suitable for both wet and dry superfine grinding of alumina, zirconium silicate, glaze, kaolin clay, quartz, feldspar, inks and ceramics in ball mill.

Product Features:

(1)Excellent wear and corrosion resistance; Chip-proof, acid-resisting, alkali-resisting, anti-abrasion, high thermal shock resistance;

(2)High density and small thickness can increase the effective ground space and increase the yield;

(3)Low wear loss and long service life (it is 3-5 times compared with nature stone liner and 23 times compared with rubber liner),which can reduce the installation times;

(4)Main material is alumina which has no pollution to the grinding object,Easy to clean;

(5)Shorten milling time and increase efficiency.

Application:

QMX High Alumina Grinding Cylinder is used as grinding media for ceramic body and glaze preparation. It’s high purity and low abrasion loss make it to be suitable for both wet and dry superfine grinding of alumina, zirconium silicate, glaze, kaolin clay, quartz, feldspar, inks and ceramics in ball mill.

Technical Data:

Specification (Size):

Product | Diameter (mm) | Height(mm) |

Cylinder | D30/40 /50/ 60 | D30/ 40/ 50 /60 |

(with chamfer ) | R0.5 | R0.5 |

Remark: Any other sizes are available upon customer’s requests. | ||

Category | HC92 | HC95 | HCT95 |

Al2O3 | ≥92% | ≥95% | ≥ 95% |

ZrO2 | / | / | / |

Density | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 |

Water Absorption | ≤0.1% | ≤0.1% | ≤0.1% |

HV 20 | ≥950 | ≥1000 | ≥1100 |

Rock Hardness HRA | ≥82 | ≥85 | ≥88 |

Bending Strength MPa | ≥220 | ≥250 | ≥300 |

Compression strength MPa | ≥1050 | ≥1300 | ≥1600 |

Fracture Toughness KIc MPam 1/2 | ≥3.7 | ≥3.8 | ≥4.0 |

Wear Volume | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 |

Benefits

> Suitable for wet grinding and dry grinding

> Forming by HIP isostatic pressing makes the cylinder’s hardness is better than the rolled grinding ball.and the chamfer edges makes the cylinder smoother to grind.

> The high purity raw material of Australia alumina powder and technology keep the media in the best to wear the abrasion and also could keep the grinding time longer than other grinding media.

Product Packaging: PE Bag (25kg/bag)+Pallet