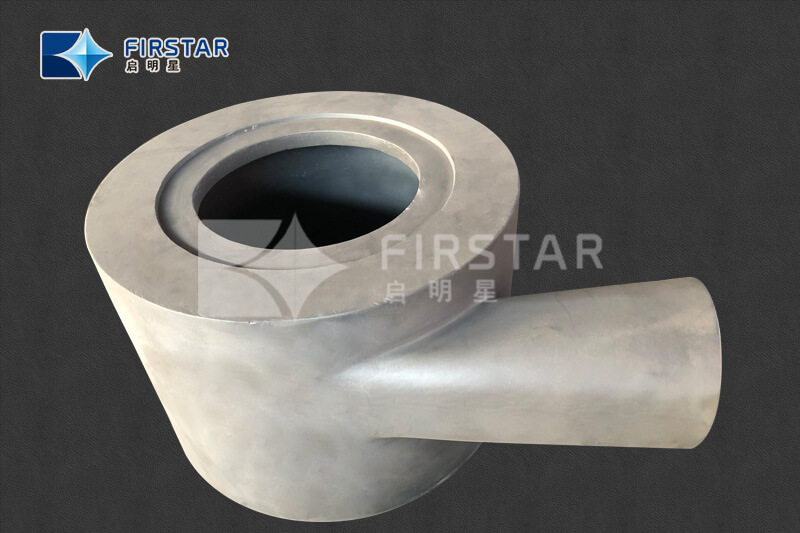

Silicon carbide Cyclone

Reaction bonded silicon carbide is a multi-phased material typically containing 7-15% silicon metal, some minor amount of unreacted carbon, with the remaining body being SiC. Reaction bonded SiC materials are manufactured utilizing a variety of processes depending on desired final product geometry, configuration, and required tolerances.

Reaction bonded silicon carbide has proven to be an excellent material choice for wear applications such as pipe liners, flow control chokes and larger wear components in the mining as well as other industries. CALSIC RB offers an economical and reliable material option for many applications where the corrosion resistance or wear resistance of CALSIC S (sintered silicon carbide) is not necessary.

Typical properties of silicon carbide are:

Excellent thermal shock resistance

Excellent hot strength

Excellent abrasion resistance

Good thermal conductivity

Relatively low coefficient of thermal expansion

Typical applications for silicon carbide are:

Kiln furniture for powder metal and ceramic processing

Kiln components including:

hearths

entrance tiles

skid rails

muffles

side walls

arches

Reaction Bonded Silicon Carbide Properties

Physical Property | Units | Typical Value |

Microstructure | % | 87% SiC, 12% Si |

Density | g/cc | > 3.02 |

Apparent Porosity | % | < 0.1 |

Max Use Temperature | °C | 1380 |

Flexural Strength | MPa | 250 @ 20°C |

Compressive Strength | MPa | 2500 |

Modulus of Elasticity | GPa | 330 @ 20°C |

Coefficient of Thermal Expansion | 1 x 10-6 in/in °C | 4.5 |

Thermal Conductivity @ 1200°C | W/mK | 45 |

Poisson's Ratio | - | 0.2 |

Vickers Hardness | GPa | 20-22 |