Wear resistant ceramic which are mainly composed of at least 90% Al2O3 are the most widely used in the world today.

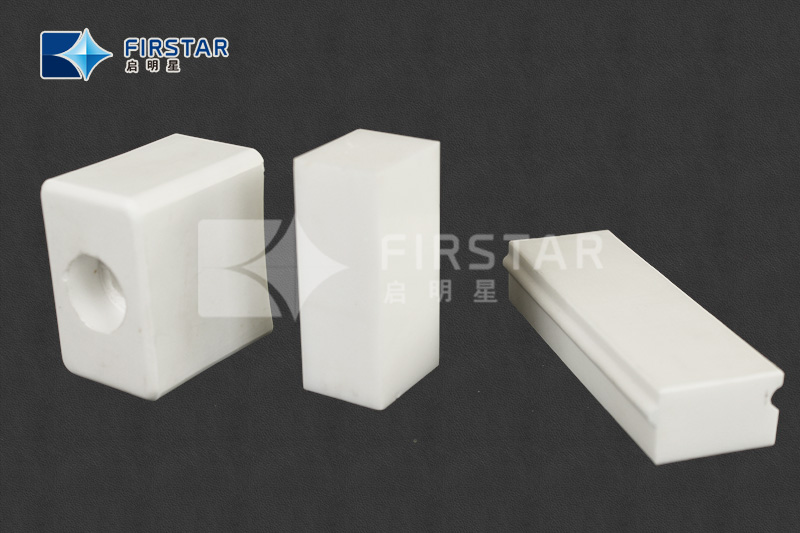

Our products are made from strictly selected alumina powder with uniform particle sizes and low CaO content.Wear resistant ceramics can be made through common dry press or isostatic pressing process and then sintering them at high temperature in the kiln. They are desirable lining materials for high wear equipment due to precise dimensions, high density,high alumina content,good flatness and stable quality.

Category | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

Density | >3.50g/ cm3 | >3.60g/cm3 | >3.65g/cm3 | >3.70g/cm3 | >3.83g/cm3 | >4.10g/cm3 | >5.90g/cm3 |

HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

Bending Strength MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

Compression strength MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

Wear Volume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

Notes: We can make alumina wear tile according to your requirement.

Features

High hardness

Rockwell hardness of high alumina ceramics is up to HRA80-90 which is second only to diamond and far exceeds wear-resistant steel stainless

Excellent wear resistance

The wear resistance of high alumina ceramics is 266 times that of manganese steel and 171.5 times that of high chromium cast iron.According to our investigation & follow-up to the clients, the service life of equipment can be prolonged over 10 times under the same working conditions.

Corrosion resistance

High alumina ceramics are inorganic oxides with extremely stable molecular structure and no electrochemical corrosion, thus they can resist erosion of acid, alkali, salt solutions and organic Solvents.

Thermostability

Working temperature of high alumina ceramics can be as high as 1400℃.

Good self-lubricity

High alumina ceramics have the properties of self-lubricity and inadhesion, the roughness is only 1/6 that of steel pipes thus less flow Resistance.

Light weight

The density of high alumina ceramics is about 3.6g/cm3, which is only half that of steel, thus easy for construction and installation

Wear solutions we provide

This is a complex process.Our engineers understand wear problems and specify

solutions to meet your operational environment. Material properties,tolerances, flatness,attachment methods, and material costs are all considered in a wear solution.

Applications • Chutes/Hoppers • Classifier Cones • Cyclone Separators • Elbows • Fan Housing & Blades • Lined Piping • Nozzles • Wear Panels |

Markets • Coal-fired Power Generation • Abrasive Material Handling • Chemical Processing • Food Processing • Iron/Steel Manufacturing • Mineral Processing • Powder/Bulk Solids Conveying • Pulp & Paper Manufacturing • Pulverizing & Grinding |